MAX-LOAD™ PLEATED FILTER BAG

Maximum particle load retained for bag filter housings

MAX-LOAD™

pleated filter bags are manufactured from the same polypropylene or

polyester needle felt material which

DURAGAF filter bags are

made from and they are formed into a pleated cylinder to

maximize surface area. MAX-LOAD filter bags have the

greatest amount of surface area of any filter bag and they

are used for minimizing the frequency of filter bag

replacements. Reduced the frequency of change-outs

also reduces labor costs, exposure to liquid and the

quantity of filter bags to be inventoried and disposed.

MAX-LOAD

pleated filter bags are manufactured from

silicon-free fibers under ISO 9001:2015 quality control standards to

ensure consistent performance.

Surface Area

Comparison of #2 size filter bags

-

SNAP-RING, UNIBAG, SENTINEL & DURAGAF : 5.2 SQFT

-

HAYFLOW: 7.5 SQFT

-

MAX-LOAD: 17.2 SQFT

MAX-LOAD

Filter Bag Design

MAX-LOAD

Filter Bag Design

The standard MAX-LOAD filter

bag has an internal core made of the same material as the

DURAGAF filter bag (polypropylene or polyester) which

undergoes a treatment process virtually eliminating

potential of fiber migration while remaining free from silicone

and other crater-forming substances.

All seams and

connections to the sealing ring are thermo bonded (welded)

to maximize the durability of the MAX-LOAD filter bag.

The internal core provides support akin to a filter bag

positioner, protecting the filter bag form downstream

pressure pulses often related to higher system pressures.

MAX-LOAD

pleated filter bags utilize a flexible crush ring seal to form both a chemically resistant

and bypass-free seal which improves as the differential

pressure increases. The sealing ring has integrally molded handles

to simplify removal from the vessel. and due to a special

surface. MAX-LOAD filter bags are provide for both #1

and #2 size filter bag vessels.

Coreless MAX-LOAD Filter Bag Design

Coreless MAX-LOAD Filter Bag Design

The

coreless version of MAX-LOAD filter bags have the look and

feel of a filter cartridge however the flow path remains

from inside-to-outside and thus particles are retained when

removing the filter bag from the vessel. Unlike the

other MAX-LOAD filter bags, the coreless version is made

from polypropylene or polyester melt-blown materials; the

same materials used for our absolute rated filter bags

CLEARGAF, ACCUGAF and PROGAF. They are constructed of

multiple layers, each graded for increasingly fine particle

retention, resulting in a wall thickness of about 0.7".

They are available with a 10 micron nylon monofilament mesh

cover for fiber sensitive applications.

Why

Go Coreless?

Whereas MAX-LOAD pleated filter

bags maximize filter area to decrease filter bag change-out

frequency, the coreless version only has 82%

less surface area (even

less surface area then a standard filter bag), so they are

used:

-

to provide maximum depth filtration for higher pressure applications that would otherwise require filter bag positioners to restrict filter bag movement

-

Retention of gelatinous/deformable particles

-

When sharp alloy particles damage needle felt filter bags

MAX-LOAD catalog pages:

Specifications:

-

#1 size MAX-LOAD bags have 8.6ft2 of filter area, 7" diameter x 14" long

-

#2 size MAX-LOAD bags have 17.2ft2 of filter area, 7" diameter x 29" long

-

Maximum temperature ratings:

-

194ºF for polypropylene material

-

275ºF for polyester material

-

-

Maximum differential pressure of 36.2 PSI

-

Recommended replacement differential pressure between 11.6 - 21.7 PSI

-

-

Maximum flow rates:

-

#1 size MAX-LOAD bags, 44 GPM (Coreless version, 55 GPM)

-

#2 size MAX-LOAD bags, 88 GPM (Coreless version, 110 GPM)

-

-

Nominal retention ratings: 1, 5, 10, 25 and 50 μm (Coreless: 1, 5, 10, 20, 50, 100 and 150 μm)

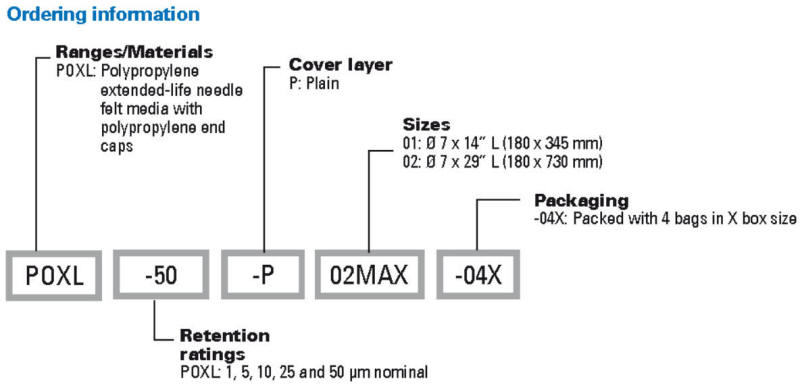

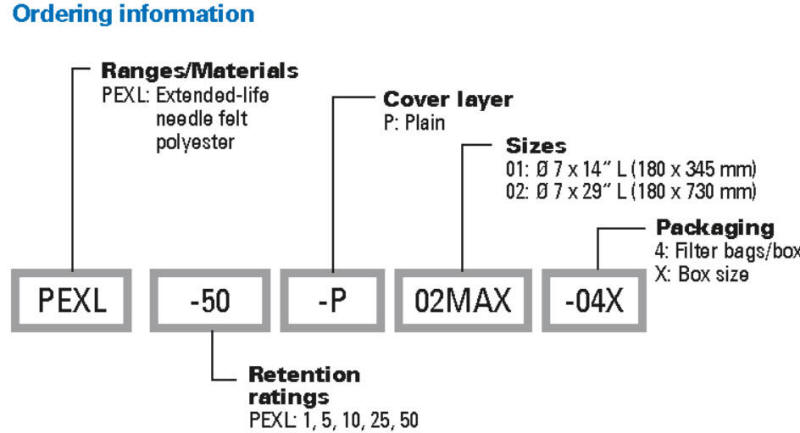

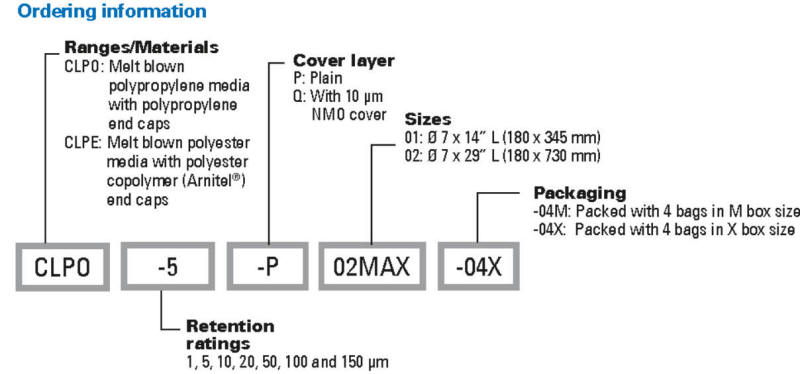

Description code system for ordering MAX-LOAD filter bags