Filter Bag Design

Style and materials of construction for filter bags

Filter Bag Styles

Filter Bag Styles

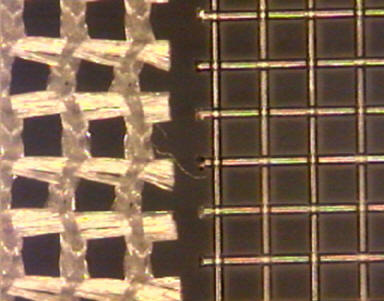

Mesh

materials consist of single filament or

multifilament woven designs manufactured using a

controlled process to ensure calibrated spacing of

the openings. Each thread intersection is

bonded to create a stabilized weave. The

single filament style is refereed to as being

"monofilament" and this design is offered in both

nylon and polypropylene materials within a 5 to 800

micron range depending upon the material. The

multifilament style is made of polyester and has a

similar grid-like design with the difference being

the lattice is made from many filaments.

Whereas monofilament filter bags provide only

surface filtration, multifilament filter bags

provide some depth filtration due to the density of

the filaments forming the grid pattern. All

mesh style filter bags have a

SNAP-RING style seal

and nominally rated retentions.

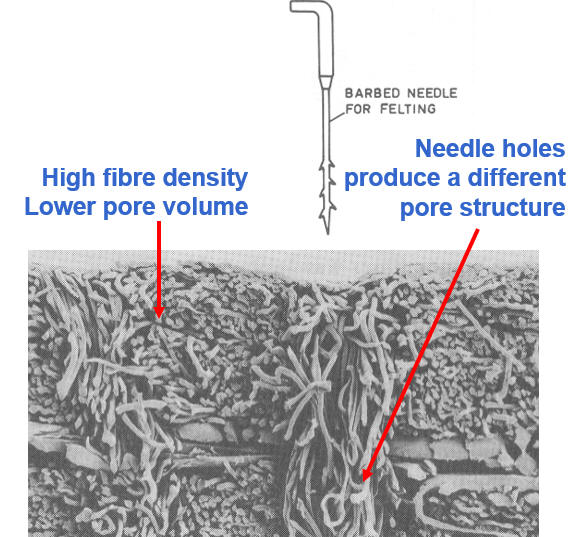

Needle felt

material is the most common filter bag material for 1 to 200 micron

nominal retentions. Simply referred to as "felt", it consists

of a layer of polypropylene, polyester, nylon, HT or Teflon®

perforated with special barbed needles from

both surfaces. The resulting pore structure is comprised of

long entangled fibers and the non-needled portion consists of a

higher density layer of compressed fiber, providing depth

filtration.

Felt filter bags become more efficient when the thickness of the felt is increased because it increases its depth filtration holding capacity. Although thicker felt filter bags cost more, they may last 3 to 5 times longer and overall reduce costs associated with purchasing, changing and disposing of filter bags. Felt material is a fairly flexible material to form which has enabled complex filter bags designs such as HAYFLOW (increases surface area by 70%) and MAX-LOAD having a particle holding capacity approximately 10 times standard felt filter bags.

Melt-blown

filter bags are made from melted polypropylene or polyester pellets which are

extruded into small diameter fibers used for forming tangled

filaments of specific

density and thickness. melt-blown filter bags provide depth

filtration and have an absolute rated retention efficiency.

The LOFCLEAR ACCUGAF and PROGAF filter bags are made of melt-blown

material and can retain particles as fine as 1 micron with 99.9%

efficiency. This type of filter

bag provides depth filtration and therefore has higher particle

loading capability.

Melt-blown

filter bags are made from melted polypropylene or polyester pellets which are

extruded into small diameter fibers used for forming tangled

filaments of specific

density and thickness. melt-blown filter bags provide depth

filtration and have an absolute rated retention efficiency.

The LOFCLEAR ACCUGAF and PROGAF filter bags are made of melt-blown

material and can retain particles as fine as 1 micron with 99.9%

efficiency. This type of filter

bag provides depth filtration and therefore has higher particle

loading capability.

Due to the precise manufacturing process the retention can be 99% efficient for particle sizes as small as 1 micron. Some filter bags are designed with several layers of varying density reserving the higher density material for only the smaller particles, increasing the overall filtration area and maximizing retention.

FILTER BAG MATERIALS

Your application will often dictate the filter bag design (mesh, felt or melt-blown) leaving the next choice to the actual material of construction. The least expensive material is polypropylene and it is a good material for filter bags because of its strength and general resistance to most industrial fluids including acids (mineral and organic) and alkalis (except NaOH and KOH). Polypropylene also has fair resistance to most organic solvents and can be used for continual operating temperatures up to 194°F.

Polyester, Nylon, HT and Teflon® materials are used for chemical and temperature compatibilities unsuitable for polypropylene. Polyester has fair resistance to most organic solvents and can be used for continual operating temperatures up to 275°F. Nylon has good resistance to alkalis and organic solvents and can be used for continual operating temperatures up to 250°F. HT is a generic reference for Nomex® and is used for high temperature fluids (up to 375°F). HT resists common alkalis and organic solvents. Teflon® is the most expensive felt filter bag material we offer but it has a very broad chemical resistance with a very high (500°F) temperature rating.