Filter Cartridge Information

call 908.362.9981 and speak with a filtration specialist for immediate assistance

This article provides an overview of Eaton’s industrial filter cartridge product line, hopefully making it easier to zero-in on the most appropriate filter cartridge for your application and to compare different designs.

Eaton’s filter cartridges are primarily designed for liquid filtration applications although their membrane and porous alloy designs have been used for aggressive gas applications.

The first step to narrow-down your choices of filter cartridges is to determine how fine of a particle you wish to retain or “block”. Filter cartridge retention is expressed in microns (μm); 1 micron = 1/1000 (0.001) millimeters. Eaton’s filter cartridges have retentions from 0.05 to 150 microns depending upon the cartridge design.

Filter Cartridge Efficiency

The next aspect to consider is the efficiency required for your application. Filter cartridge and filter bag media are described as having either "nominal" or "absolute" efficiency for a given particle retention size.

Nominal Efficiency

Nominally rated filter media is the most common media used for filter cartridges and filter bags. Their filtration efficiency is determined by the percentage of particles filtered out under specific test conditions. In the industrial filtration industry, the test conditions are left to the manufacturer and usually their efficiency is not overtly stated in sales literature. I believe Eaton’s nominally rated filter cartridges are approximately 70% efficient unless otherwise specified. Therefore, with a new nominally rated filter cartridge, ≥70% of the particles used in the test were retained by the filter cartridge. As particles become trapped within the filter cartridge media, the open area available decreases and thereby increases the efficiency of the filter cartridge. Nominal rated filter cartridges are usually relatively inexpensive compared to absolute rated filter cartridges and thus used for less critical applications; often as "pre-filters" to reduce the loading on the more expensive "absolute" efficiency cartridges.

"Absolute" Efficiency

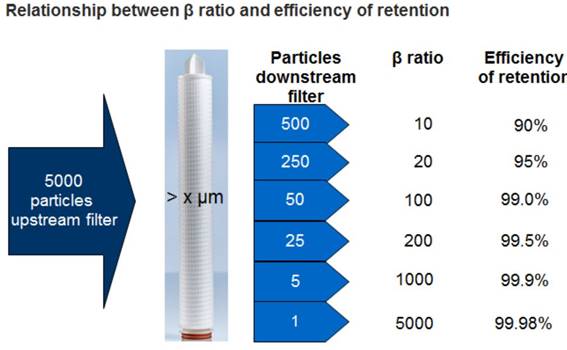

Also referred to as “rated efficiency” refers to a laboratory defined retention efficiency, often expressed as a Beta Ratio which refers to the percentage of all particles of a given size that are effectively filtered-out.

The Beta Ratio is established via laboratory testing and consists of the number of particles up-steam of the filter divided by the number of particles downstream of the filter for the targeted particle size. The efficiency is calculated via the ratio of particles retained from the total number of particles used in the test.

Therefore, a Beta ratio of 5000 means that for every particle of a given size that bypasses the filter cartridge, there were 4999 that did not. The math follows:

Beta 5000 = 4999 particles retained from a total of 5000 ∴ 4999/5000 = 99.98% efficiency.

Most of our absolute rated filter cartridges have a Beta Ratio chart illustrating their efficiency for a given particle size at the bottom of their webpage and you can also find the Beta Ratio efficiency chart on the last page of Eaton’s datasheet for each cartridge model. Links to Eaton’s specification sheets are included within our webpages by filter cartridge model.

You will notice several beta ratios for a given filter cartridge because there is a specific efficiency for each particle size tested.

Example: the LOFPLEAT-HF 1.0-micron filter cartridges have a Beta 1000 or 99.90% retention efficiency for particles ≥ 1.0 microns. They are also Beta 100 (99%) efficient for retention of particles ≥ 0.60 microns AND Beta 50 (98%) efficient for retention of particles ≥ 0.30 microns.

The testing method used for Eaton’s Beta Ratios is based upon a "single-pass test method" using ambient water at a flow rate of 2.5 GPM for a 10" length cartridge. The type of particles used during testing are latex beads and special "coarse and fine test dust" (it is actually “engineered dust” specifically curated for such testing!). The removal efficiencies are determined using multiple laser particle counters - the most sophisticated and effective method of counting dust particles.

The actual efficiency received for your application will differ due to operating conditions such as pressure fluctuations, differences in temperature and viscosity. The design of the filter vessel is another factor contributing to overall filtration efficiency.

Be careful not to confuse filtration efficiency with particle retention capacity; they are unrelated. The total volume of particles that can be retained within a cartridge and the increased efficiency due to reduction of the open area available are not reflected in the Beta Ratio and testing.

Much of the performance advantages provided by Eaton’s filter cartridges are related to manufacturing technology. They offer different materials and physical configurations in support of higher volume particle retention at minimal differential pressure without sacrificing retention efficiency.

After determining how fine you need to filter to and whether or not you require an absolute rated filter cartridge design, the next aspect to consider is the total surface area required for your flow rate, which will equate to the size and number of filter cartridges required.

Filter Cartridge Sizes

Eaton offers the four most common "industry standard" filter cartridge sizes, referred to by their nominal length of 10", 20", 30" and 40"; sometimes slightly shortened versions are required and that's not an issue, shortening a cartridge is easy enough to do and does not affect pricing. It is no coincidence that the standard filter cartridge sizes are all multiples of 10; lengths >10” are achieved by attaching additional 10” length cartridges together. Filter cartridge housings can be designed to accommodate multiple filter cartridges in support of higher flow rates.

Filter Cartridge Designs & Applications

There are (4) basic industrial Eaton filter cartridge designs: membrane, pleated, melt blown and porous metal. Each design lends itself to specific types of applications. Following is a quick reference chart for common application categories.

Membrane

An absolute efficiency rated filter cartridge; this style provides the finest retention of all Eaton’s filter cartridge designs. They are manufactured with a single layer of PES or PTFE membrane for retentions as fine as 0.05 microns; most are manufactured within a cleanroom environment.

Pleated

This design increases the total surface area available by folding or “pleating” the media around a center core. Also made from absolute rated efficiency material, they can be used to filter as fine as 0.1 microns. Some designs consist of multiple filter layers for increased particle retention capacity.

Porous Metal

Another absolute rated efficiency filter cartridge design, LOFMET filter cartridges are constructed from sintered stainless steel or titanium. Compared to the other filter cartridge designs these are expensive, but they are often the only choice for aggressive chemistry or extreme temperatures that are not compatible with non-alloy filter cartridges.

Melt Blown

This is a nominally rated filter cartridge design consisting of multiple “zones” of retention to maximize the amount of depth filtration received. There are designs as fine as 0.5 microns and due to the manufacturing process, their performance is very repeatable and their cost relatively inexpensive compared to other manufacturing methods.

A Different Approach

Whereas most industrial filtration websites provide just basic specifications for their products (mostly a paraphrased copy of the manufacturers datasheet) and leave it to the user to research many websites to figure-out what they need, our website is designed to inform and educate.

Our websites are structured to make it easier to determine exactly what you need for your application. The information is grouped from informative, specifications and model based groupings to intuitively find the information you are looking for fast!

Please visit our website at

https://fdpp.com, it is the hub to connect to

all of our websites related to filtration, pumps and valves. Our article

section contains links to over 60 informative articles which are also

interwoven throughout our navigation menu.

Best of all? We are a simply phone call away! Call us at 908.362.9981 during 9-5 EST M-F and you will speak to a factory trained sales person that can discuss you specific application immediately! No forms to fill-out, no waiting, just call and have your questions answered, we like to keep it simple!