call 908.362.9981 and speak with a filtration specialist for immediate assistance

There are many different styles of bag filter housings to choose from and

this article will help you determine which is the best fit for your application.

Simplex bag filter vessels require the flow rate to be interrupted or diverted to safely access the filter bag chamber(s).

Eaton

Ecoline filter housing:

Used for "light duty" applications and rated for a maximum pressure

of only 100 PSI, the Ecoline has a clamp style closure and is only

available in 316SS material with FNPT threaded connections. It does

have some notable features, such as an investment cast concave

chamber cover which displaces some fluid so that when the chamber is

opened the fluid level is below the edge of the vessel. We can

modify the vessel to have differential pressure ports, but that is

about as much "customization" this design offers. The Ecoline

cannot be ASME code stamped and filter bag sealing is assisted by a

separate internal spool which transfers the downward pressure of the

lid closure across the circumference of the filter bag. This

type of sealing is characteristic of all our housing designs EXCEPT

the Topline

and therefore applications requiring high efficiency particle

retention (greater than 65%) and especially for particle retention

<50 microns, the Topline design should be utilized.

Eaton

Ecoline filter housing:

Used for "light duty" applications and rated for a maximum pressure

of only 100 PSI, the Ecoline has a clamp style closure and is only

available in 316SS material with FNPT threaded connections. It does

have some notable features, such as an investment cast concave

chamber cover which displaces some fluid so that when the chamber is

opened the fluid level is below the edge of the vessel. We can

modify the vessel to have differential pressure ports, but that is

about as much "customization" this design offers. The Ecoline

cannot be ASME code stamped and filter bag sealing is assisted by a

separate internal spool which transfers the downward pressure of the

lid closure across the circumference of the filter bag. This

type of sealing is characteristic of all our housing designs EXCEPT

the Topline

and therefore applications requiring high efficiency particle

retention (greater than 65%) and especially for particle retention

<50 microns, the Topline design should be utilized.

Eaton Miniline Filter Housing: A version of the Ecoline above designed to be used with smaller size filter bags (#3 and #4 sizes). Reserved for low flow rate applications when a compact size/footprint is desired, they are not much different in cost from the "full size" (#1 and #2 size) Ecoline and Flowline II bag filter housings.

Eaton

Flowline II Filter Housing: This is an inexpensive version of the

Flowline

housing design, having some additional material options compared to

the Ecoline (carbon steel, 304SS and 316SS), Flowline II vessels are

rated to 150 PSI due to its swing bolt closure and are offered with

flanged or threaded connections. Their body is hydro formed,

reducing the number of weld areas, promoting a smoother internal

finish. While the manufacturing process reduces the cost of

the Flowline II, it also means that customizations such as adding

differential pressure taps, surface polishing and non-standard

connections are not available. As with the Ecoline above, this

entry-level housing is designed for nominally rated filter bag

applications where an ASME code stamp is not required.

Eaton

Flowline II Filter Housing: This is an inexpensive version of the

Flowline

housing design, having some additional material options compared to

the Ecoline (carbon steel, 304SS and 316SS), Flowline II vessels are

rated to 150 PSI due to its swing bolt closure and are offered with

flanged or threaded connections. Their body is hydro formed,

reducing the number of weld areas, promoting a smoother internal

finish. While the manufacturing process reduces the cost of

the Flowline II, it also means that customizations such as adding

differential pressure taps, surface polishing and non-standard

connections are not available. As with the Ecoline above, this

entry-level housing is designed for nominally rated filter bag

applications where an ASME code stamp is not required.

Eaton Flowline Filter Housing: This is the entry-level housing for industrial applications that do not require an ASME code stamp. Since the manufacturing technique involves additional welding, its more expensive than the Flowline II but it also enables non-standard connection types, differential pressure taps and surface polishing.

Eaton Sideline Filter Housing: These filter bag housings can be customized more than the above, to include features such as steam jacketing, side outlet location and can be ASME UM or U stamped; CRN registration is also supported with this design. Features such as a concave displacement cover and a hold down spool are standard and similar to the other designs mentioned above.

Eaton

Topline Filter Housing: Featuring a "goose neck" or "over-the-top"

inlet design, the Topline style housing represents the best sealing

capability of all bag filter housing designs. This is because

a hold-down spool is not required to seal the filter bag to the

vessel, rather the chamber cover directly interfaces with the bag

sealing ring and forms a bypass-free seal. This type of direct

seal with the filter bag is only possible with this inlet

configuration as it enables the filter bag to be placed at the top

rim of the vessel. The additional complexity of this

design contributes to its higher cost, but for applications

requiring efficient retention of particles smaller than 50 microns,

it is the best design to use. This ASME code

stamped vessel can be polished internally or externally as well as customized with

special connections, a steam jacket or differential pressure

connections.

Eaton

Topline Filter Housing: Featuring a "goose neck" or "over-the-top"

inlet design, the Topline style housing represents the best sealing

capability of all bag filter housing designs. This is because

a hold-down spool is not required to seal the filter bag to the

vessel, rather the chamber cover directly interfaces with the bag

sealing ring and forms a bypass-free seal. This type of direct

seal with the filter bag is only possible with this inlet

configuration as it enables the filter bag to be placed at the top

rim of the vessel. The additional complexity of this

design contributes to its higher cost, but for applications

requiring efficient retention of particles smaller than 50 microns,

it is the best design to use. This ASME code

stamped vessel can be polished internally or externally as well as customized with

special connections, a steam jacket or differential pressure

connections.

Eaton Polyline Filter Housing and Hayward FLV Filer Housing: Represent our non-alloy designs (PVC, CPVC and PVDF). These are typically used for non-alloy pipelines and thus have some limitations; they cannot be ASME code stamped, polished or steam jacketed and their flow rates are typically limited to a maximum of 100 GPM. These are more expensive than their alloy counterparts and chosen for aggressive chemistries which otherwise would require expensive, "exotic" alloys.

All of the bag filter vessels above are single chamber, simplex designs. Therefore the flow rate is limited to the capacity of the single filter bag used within it and the process needs to be interrupted to change-out the filter bag.

To accommodate flow rates above 180 GPM, using specialty filter bags having a reduced flow capacity or for viscous fluids, using multiple chambers (filter bags) simultaneously is required.

MULTIPLE CHAMBER DESIGNS

Eaton

Douline Filter Housing: Consist of two bag filter housings connected

by a common inlet and outlet manifold and thus having double the

capacity of a single chamber design; there are no valves to divert

flow, flow passes through both chambers simultaneously.

Eaton

Douline Filter Housing: Consist of two bag filter housings connected

by a common inlet and outlet manifold and thus having double the

capacity of a single chamber design; there are no valves to divert

flow, flow passes through both chambers simultaneously.

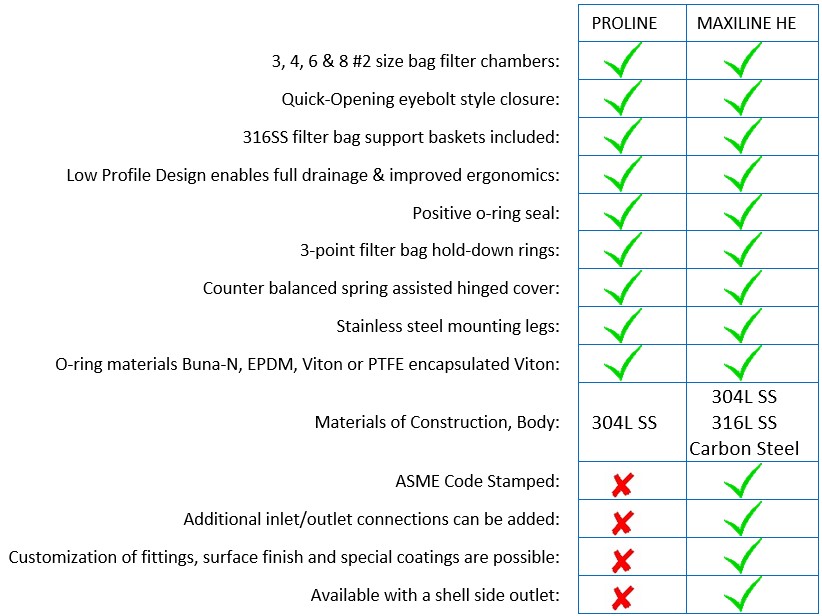

Within the 3, 4, 6 and 8 chamber range there are several design options

offered.

This

MBFH is generally the least expensive design, available in a wide range of

materials and is the only option for 10+ chamber models. Some

Manufacturers offer the outlet nozzle welded tangentially to the

bottom dish as compared to using an elbow at the bottom of the dish

and this significantly reduces the height of the MBFH assembly.

This reduction in height often eliminates a requirement for ladders

and scaffolding around the housing and it is actually safer to be

located firmly on the ground without having to strain for filter bag

access.

Counter weighted spring assisted hinged covers can be opened and closed

safely by a single individual. This fantastic feature costs about 10% more

when compared to the lifting davit style, justified with its reduced footprint

and improved ergonomics.

While swing bolts provide relatively quick access to the filter vessel,

access is further improved with a gear operated clamp closure which ensures

positive and equal sealing across the chamber cover sealing area.

ECONOMY MODELS

Eaton MAXILINE Filter Housing and Eaton PROLINE Filter Housing vessels have the same basic features and flow capacity. However, the PROLINE is only available in 304L SS and is not available with an ASME code stamp. If your application is compatible with less expensive carbon steel material or requires 316L SS (or other customizations with or without an ASME code stamp), then the MAXILINE design is the way to go.

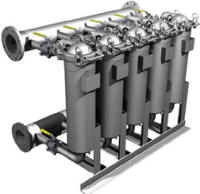

Another way to approach high flow rate filtration applications is using several standard single filter bag vessels connected to a common inlet and outlet/drain manifold. An advantage of this approach is that, when properly sized, individual housings can be isolated and filter bags replaced without needing to shut down or “duplex” the system and thus can significantly reduce initial costs.

The filter housings can be oriented on both sides of an inlet/outlet header to

shorten its length and if you extend these headers, it will enable adding

additional filter stations in the future.

DUPLEXED FILTER HOUSINGS

When your process cannot be interrupted to change filter bags and you are not using the Moduline configuration above, we can supply a pair of simplex housings connected by a common manifold having diverting valves to isolate the chamber to be serviced.

Flow Rate (chamber size and number of chambers required)

The size of the bag filter vessel (number of filter bag chambers) depends upon the diameter and length of the filter bags required for your specific application. The four "industry standard" filter bag sizes are referred to as being #1, #2, #3 or #4 sizes, with #1 and #2 sizes being the most common for industrial applications.

When you complete our inquiry form

or otherwise contact us by email or phone, our filtration experts will

gather information about the filter bag aspect of your application to ensure

the most appropriate bag filter housing is suggested. Our filter bag website

provides detailed information and specification sheets for a variety of

filter bag types, complementing our filter bag housing website.