PROGAF™ FILTER BAGS

Ultra High Efficiency Filter Bags

PROGAF

filter bags provide BETA 5000 retention

efficiencies with a high performance, multilayer

design that rivals the performance of filter cartridges.

PROGAF filter bags are manufactured from melt-blown polypropylene

and have a special layered "step" crush seal style filter bag to

eliminate particle bypass in support of 1 micron particle retention

with 99.9%. This equates to a BETA 5000 ratio or

retention of 4999 of 5000 one micron sized test particles during

laboratory testing. The ultra pure polypropylene filaments

used in the construction of PROGAF filter bags are silicon free and

subject to rigorous ISO 9001:2015 quality control procedures to

ensure performance. PROGAF filter bags are hydrophobic and are

in compliance with the FDA

requirements according to title 21, Section 177 and the EC

Directives 1935/2004 and 2002/72/EC for contact with food and

beverages. All layers of PROGAF filter bags terminate to a

common welded seam.

PROGAF

filter bags provide BETA 5000 retention

efficiencies with a high performance, multilayer

design that rivals the performance of filter cartridges.

PROGAF filter bags are manufactured from melt-blown polypropylene

and have a special layered "step" crush seal style filter bag to

eliminate particle bypass in support of 1 micron particle retention

with 99.9%. This equates to a BETA 5000 ratio or

retention of 4999 of 5000 one micron sized test particles during

laboratory testing. The ultra pure polypropylene filaments

used in the construction of PROGAF filter bags are silicon free and

subject to rigorous ISO 9001:2015 quality control procedures to

ensure performance. PROGAF filter bags are hydrophobic and are

in compliance with the FDA

requirements according to title 21, Section 177 and the EC

Directives 1935/2004 and 2002/72/EC for contact with food and

beverages. All layers of PROGAF filter bags terminate to a

common welded seam.

The

sealing ring is referred to as a STEP-RING and its multiple step

design corresponds with the multiple layer design of PROGAF filter

bags, which have as many as 12 layers. The seal of a crush

seal design filter bag improves with an increase in

differential pressure. The filter bag seal is made from

polypropylene and each filter bag layer is welded to the sealing

ring. The integrally molded handles simplify removal from the

filter housing.

The

sealing ring is referred to as a STEP-RING and its multiple step

design corresponds with the multiple layer design of PROGAF filter

bags, which have as many as 12 layers. The seal of a crush

seal design filter bag improves with an increase in

differential pressure. The filter bag seal is made from

polypropylene and each filter bag layer is welded to the sealing

ring. The integrally molded handles simplify removal from the

filter housing.

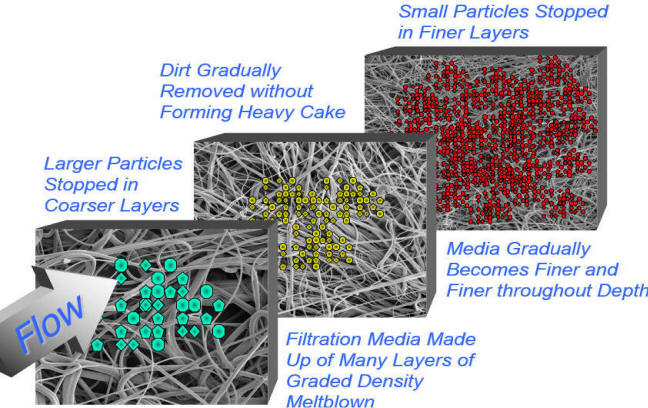

The combination of several filtration layers optimizes the particle retention holding capacity by distributing the coarser particles within the outer layers and finest particles within the inner layers. The progressively finer structure of PROGAF filter bags is akin to using several bag filter housings in series and thus reduces the number of bag filter housings and filter bags and the associated downtime corresponding to filter bag changes. The outermost layer consists of polypropylene mesh to prevent fiber migration.

Specifications:

-

5.2ft2 of filter surface area

-

Maximum temperature rating of 194ºF

-

Maximum differential pressure of 36 PSI

-

Recommended replacement differential pressure between 11.6 - 21.7 PSI

-

-

Maximum flow rate 44 GPM

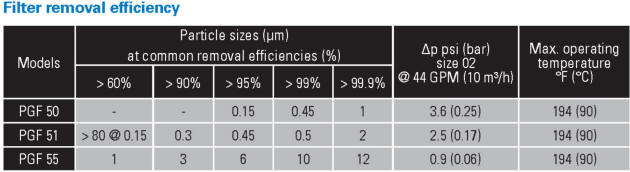

There are (3) PROGAF filter bags made in the universal #2 size (7" diameter x 32" long) having BETA 5000 (99.9%) efficiencies of 1, 2 and 12 microns.