HAYFLOW™ Filter Bags

#1 and #2 size filter bags which last 3-5 times longer!

Filter

bags for #2 size bag filter vessels have a 7" diameter opening and

32" length, resulting in a total surface area of 5 SQFT, limiting

the maximum flow rate to approximately 176 GPM. The HAYFLOW

filter bag design has a more complex geometry, increasing its

surface area by 50% for a total of 7.5 SQFT.

How

is that possible?

Filter

bags for #2 size bag filter vessels have a 7" diameter opening and

32" length, resulting in a total surface area of 5 SQFT, limiting

the maximum flow rate to approximately 176 GPM. The HAYFLOW

filter bag design has a more complex geometry, increasing its

surface area by 50% for a total of 7.5 SQFT.

How

is that possible?

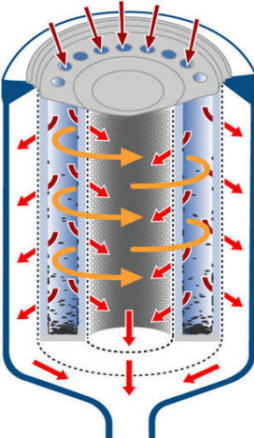

HAYFLOW filter bags require a special restrainer (support) basket

designed to support and position the additional filter bag material.

Whereas a standard support basket is cylindrical shaped, having a 7"

diameter opening and either a flat or conical bottom, the HAYFLOW

support basket has an additional cylindrical shaped protrusion

extending upwards from the bottom center of the support basket.

The HAYFLOW filter bag has the same shape and thus its appearance is

best described as an inverted basket within a basket.

HAYFLOW filter bags require a special restrainer (support) basket

designed to support and position the additional filter bag material.

Whereas a standard support basket is cylindrical shaped, having a 7"

diameter opening and either a flat or conical bottom, the HAYFLOW

support basket has an additional cylindrical shaped protrusion

extending upwards from the bottom center of the support basket.

The HAYFLOW filter bag has the same shape and thus its appearance is

best described as an inverted basket within a basket.

This ingenious design enables your #2 size bag filer housing to handle higher flow rates and will last from 3 to 5 times longer than conventional #2 size filter bags. Although the HAYFLOW filter bags cost approximately twice the cost of a SENTINEL filter bag, on an annual basis the reduction of filter bags requires coupled with the reduction in labor, downtime and disposal costs add-up to a significant savings. Another cost savings benefit is the reduction of liquid carry-out, which is the volume of liquid retained within a clogged filter bag. A conventional #2 size filter bag holds 4.5 gallons whereas the HAYFLOW filter bag holds only about 1 gallon of liquid; a savings of 3.5 gallons of process liquid per filter bag change! Less retained liquid also equates to a lighter and easier to remove filter bag in support of improved ergonomics.

HAYFLOW

filter bags are manufactured from polypropylene or polyester

needle felt materials to provide 1 to 100 micron nominal particle

retention. The seams and crush style sealing ring are welded,

not sewn, maximizing the strength and durability of the filter bag.

Handles are molded into the sealing ring to assist personnel with

removing it from its support basket. The needle felt material

is per the DURGAF design, a thicker material increasing the particle

retention capaicty due to the additional depth of the material.

The sealing ring is designed to create a laminar flow directling

large partilcles towards the bottom of the filter bag.

HAYFLOW

filter bags are manufactured from polypropylene or polyester

needle felt materials to provide 1 to 100 micron nominal particle

retention. The seams and crush style sealing ring are welded,

not sewn, maximizing the strength and durability of the filter bag.

Handles are molded into the sealing ring to assist personnel with

removing it from its support basket. The needle felt material

is per the DURGAF design, a thicker material increasing the particle

retention capaicty due to the additional depth of the material.

The sealing ring is designed to create a laminar flow directling

large partilcles towards the bottom of the filter bag.

Most #2 size

bag filter housings can be retrofitted with HAYFLOW support baskets

and filter bags, which is less expensive than increasing the number

or size of bag filter housings to handle higher flow rates. In

the case of multiple bag filter housings, using HAYFLOW filter bags

can reduce the number of filter bag chambers required, asignificant

cost savings.

Specifications:

-

#2 size HAYFLOW bags have 7.5ft2 of filter area and are 7" diameter x 32" long

-

Maximum temperature ratings:

-

194ºF for polypropylene material

-

302ºF for polyester material

-

-

Maximum differential pressure of 36.2 PSI

-

Recommended replacement differential pressure between 11.6 - 21.7 PSI

-

-

Maximum flow rate: 176 GPM

-

Nominal retentions: 1, 5, 10, 25, 50 and 100 μm