DURAGAF™ Filter Bags

Extended Life Filter Bags last 2 to 5 Times Longer and only cost $9.69 each!

DURAGAF

filter Bags are high performance, fully welded, needle felt filter bags manufactured from

silicon-free fibers under ISO 9001:2015 quality control standards to

assure consistency of retention performance. To extend the

particle retention capacity, finer fibers are used and the thickness

is increased. Finer fibers increase the porosity, enabling the

use of thicker media to increase the volume of particles which can

be retained, including gelatinous and

deformable particles. DURAGAF filter bags typically last 2 to 5 times longer than standard

needle felt filter bags, equating to a reduction in annual

quantity of filter bags used, frequency of labor, downtime and disposal

costs.

DURAGAF

filter Bags are high performance, fully welded, needle felt filter bags manufactured from

silicon-free fibers under ISO 9001:2015 quality control standards to

assure consistency of retention performance. To extend the

particle retention capacity, finer fibers are used and the thickness

is increased. Finer fibers increase the porosity, enabling the

use of thicker media to increase the volume of particles which can

be retained, including gelatinous and

deformable particles. DURAGAF filter bags typically last 2 to 5 times longer than standard

needle felt filter bags, equating to a reduction in annual

quantity of filter bags used, frequency of labor, downtime and disposal

costs.

DURAGAF filter bags are manufactured from polypropylene or polyester needle felt material and have crush style sealing rings made of polypropylene, polyester or Santoprene. The filter bag seal to the support basket and housing improves with an increase in differential pressure to help ensure particles do not bypass the filter bag. Each sealing ring has integrally molded handles which are easy to grab for bag removal. All materials used in the construction of DURAGAF filter bags comply with FDA requirements with regards to food and beverage contact.

The welded manufacturing process results in a special surface finish to significantly reduce fiber migration. The filter bag seams and sealing ring are welded to maximize their durability. All popular filter bag accessories to improve efficiency, such as filter bag positioners, magnetic inserts and displacement balloons are compatible with DURAGAF filter bags.

DURAGAF filter bags often ship from stock but could take as long as 8 weeks as it depends upon where the factory is in the stock replenishment cycle. We can allocate reserved inventory for your company to support JIT deliveries. If lead time is critical please Call us at 908.362.9981 to confirm cost and lead time and we will log into the Eaton system to check status while you are on the phone.

DURAGAF Applications:

-

Water treatment

-

Chemicals manufacturing

-

paints, varnishes and coatings

-

Adhesives

-

Petrochemical

-

Automotive

-

Primary metals manufacturing

-

Food & beverage

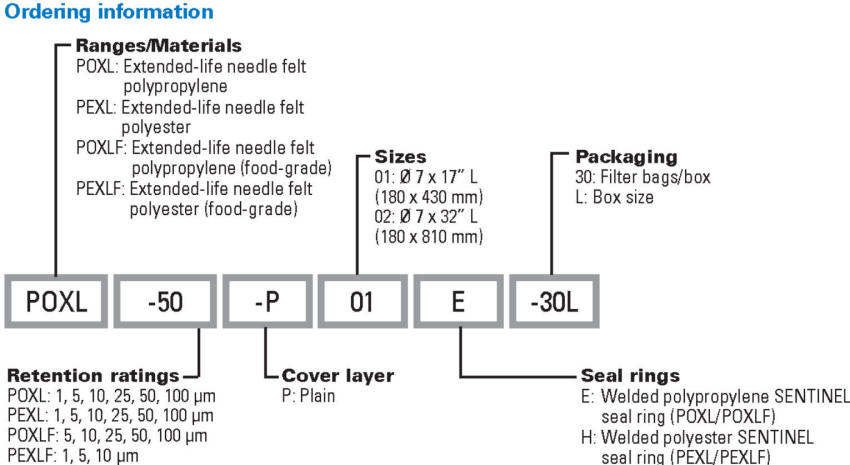

DURAGAF filter bag specifications:

-

#1 size DURAGAF™ bags have 2.6ft2 of filter area and are 7" diameter x 17" long

-

#2 size DURAGAF™ bags have 5.2ft2 of filter area and are 7" diameter x 32" long

-

Maximum temperature ratings:

-

194ºF for polypropylene material

-

302ºF for polyester material

-

-

Maximum differential pressure of 36.2 PSI

-

Recommended replacement differential pressure between 11.6 - 21.7 PSI

-

-

Maximum flow rates:

-

#1 size DURAGAF™ bags, 66 GPM

-

#2 size DURAGAF™ bags, 132 GPM

-