FLOWLINE BAG FILTER HOUSINGS

Industrial design bag filter housings

The

FLOWLINE model bag filter housing is an "economy" version of the

SIDELINE bag

filter housing and should

be considered when ASME code stamping is not required. Its

hydro formed body is not applicable to ASME code and therefore If you

require an ASME code stamp, CRN or steam jacketing, the

SIDELINE bag

filter housing or

TOPLINE bag

filter housing models should be considered.

The

FLOWLINE model bag filter housing is an "economy" version of the

SIDELINE bag

filter housing and should

be considered when ASME code stamping is not required. Its

hydro formed body is not applicable to ASME code and therefore If you

require an ASME code stamp, CRN or steam jacketing, the

SIDELINE bag

filter housing or

TOPLINE bag

filter housing models should be considered.

The FLOWLINE filter housing is designed to be used with any nominally rated #1 and #2 size filter bag, typically offered in the 1 to 800 micron retention range. If you require a specified efficiency (absolute rated) filter bags, you should use the TOPLINE design. FLOWLINE bag filter housings are suitable for pressures as high as 150 PSI and temperatures up to 400F. Manufactured in both carbon steel and 316 stainless steel, they are offered with 2" threaded as well as 2" and 3" 150# ANSI flanged connections.

Each FLOWLINE bag filter housing has a swing

bolt cover which can be hinged in any one of four positions.

The cover itself is referred to as an "evacuation cover" - a

concave design that increases the ullage (empty space) within the

filter housing. The advantage is twofold: there is less

"wasted fluid" during a bag change and the fluid level ends up lower

in the housing to reduce spillage once the cover is opened. An

added benefit is protecting personnel from the liquid as less leaves

the filter housing. The cover is an investment cast component,

ensuring precise, reliable sealing with concentric downwards

pressure onto the bag hold-down ring.

Each FLOWLINE bag filter housing has a swing

bolt cover which can be hinged in any one of four positions.

The cover itself is referred to as an "evacuation cover" - a

concave design that increases the ullage (empty space) within the

filter housing. The advantage is twofold: there is less

"wasted fluid" during a bag change and the fluid level ends up lower

in the housing to reduce spillage once the cover is opened. An

added benefit is protecting personnel from the liquid as less leaves

the filter housing. The cover is an investment cast component,

ensuring precise, reliable sealing with concentric downwards

pressure onto the bag hold-down ring.

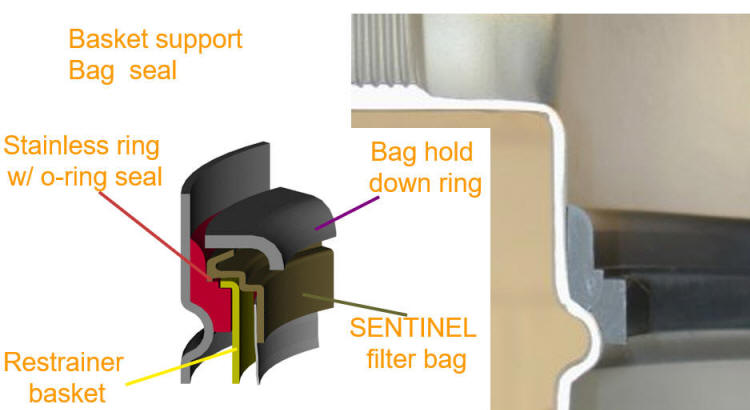

The bag hold down ring is what transfers the pressure of the closed cover onto the sealing surface of the filter bag to form a seal between the filter bag and filter housing. This type of seal is also used for the ECOLINE bag filter vessels, consisting of an o-ring seated onto the beaded internal circumference of the filer vessel which supports the perforated stainless steel restrainer basket. The filter bag seal is compressed against the restrainer basket because the hold down ring is sandwiched between the housing cover and restrainer basket. The illustration below shows a SENTINEL style filter bag having a crush seal however SNAPRING style filter bags can be used as well - you just do not require the hold down ring. The SENTINEL style filer bag seal is used for absolute rated as well as nominally rated filter bag designs, although if your application requires ultra efficient sealing or retention of particles smaller than 50 microns the TOPLINE bag filter housing should be used.

The restrainer (support) basket is made of 316SS and has 9/64" perforations which are easier to clean than older mesh style restrainer baskets. FLOWLINE bag filter housings have adjustable epoxy powder coated steel mounting legs to fine-tune the inlet/outlet elevation.

FLOWLINE customizations

The FLOWLINE bag filter housing can be provided with differential pressure traps and gauge to simplify awareness of when filter bags require changing. We can also supply them with tri-clover inlet/outlet connections. In support of food, beverage, biopharmaceutical and fine chemical applications requiring highly polished surfaces, FLOWLINE bag filter housings can be electro polished inside and out. If your application has a high percentage of particulates, consider swapping-out the standard restrainer basket for the HAYFLOW restrainer basket and use corresponding HAYFLOW filter bags.

FLOWLINE bag filter housings are also compatible with magnetic inserts to increase filtration efficiency of ferrous particles as described in our article Enhancing filtration with magnetism.

Flexibility in flow configuration

The FLOWLINE bag filter outlet can be placed at the bottom, at the opposite side or even the same size ("loop") positions depending upon which orientation fits your application best.

Bag Filter Installation Manual

Outline Drawings: