Eaton acquired Hayward

in 2005 (which included the Hayward acquisitions of Loeffler [’98] and GAF

[’99]) to establish an industrial filtration division. Subsequently

they acquired Ronningen-Petter®, Internormen Technology®

and Begerow® filtration among others to build the most diverse

industrial filtration product offering in the world. One of the

consequences of all these acquisitions is the difficulty of comparing an

overlap of similar products in addition to improved designs based upon new

manufacturing technology. In the case of Eaton’s bag filtration

product line, they have several similar products which can be used for the

same application, so how does one figure-out the “best” design for their

application?

You can read the sales literature to identify the

nuances of each design, make a chart and figure it out for yourself, but I

thought I’d make it easier with this article comparing Eaton’s PROLINE and

MAXILINE models of multiple bag filter housings.

What is a multiple bag filter housing?

A bag filter housing is a pressure vessel

designed to contain a disposable fabric media for filtering from 1 to 800

microns. The filter media are referred to as filter bags or sometimes

filter socks because like a bag or sock only one end is open. Dirty

fluid enters through the open end and particles get caught within the filter

bag material with only “filtered” fluid passing through. A multi-bag

filter housing contains anywhere from 2 to 24+ individual filter bags.

Each filter bag has a certain flow rate capacity, so using one vessel

containing multiple bags enables fine filtration of higher flow rates.

Eaton offers two basic multi-bag filter housings

called PROLINE and MAXILINE. The relatively new PROLINE takes

advantage of advanced manufacturing techniques to provide an economical

alternative to the MAXILINE style bag filter housings. Specifically,

the PROLINE series uses investment cast dished heads and internal tube sheet

assembly to reduce costs and welding procedures. PROLINE bag filter

vessels are a viable alternative if your application:

-

has a flow rate of up to 1000 GPM with an operating pressure ≤ 150 PSIG

-

is compatible with 304 stainless steel

-

does not require an ASME U code stamp

PROLINE bag filter housings hold three to eight

#2 size filter bags which are 7” diameter by 32” long. Nominally rated

versions of these filter bags each have a flow rate capacity of about 132

GPM and that’s how we end-up with an approximate 1000 GPM flow range at

pressures up to 150 PSIG. The maximum capacity of #2 size filter bags is

affected by the bag’s efficiency (nominal or absolute rated), viscosity and

perhaps even the particulate load. When we assist with an application,

we take such factors into consideration to recommend the appropriate number

of bag filter chambers.

The PROLINE series of bag filter housings

(available in 3, 4, 6 and 8 chamber designs) was developed in 2012 by Eaton

to fill the need for an economical bag filter housing which does not require

an ASME code stamp, because most applications do not require stamping.

Until the PROLINE, bag filter housings were made from fabricated dished

heads and filter bag chambers, labor-intensive processes involving lots of

welding and non-destructive examination procedures which contribute to the

cost of the vessel. PROLINE vessels use cast components to reduce

welding and polishing procedures along with generating less material waste.

Cast dished heads can provide the required structural integrity for the

design pressure of 150 PSI with less material. Such components are not

covered in ASME code stamped requirements and thus these cannot be ASME code

stamped.

PROLINE bag filters share the same

characteristics of the MAXILINE vessels to reduce filter bag change-out

times and personnel safety hazards.

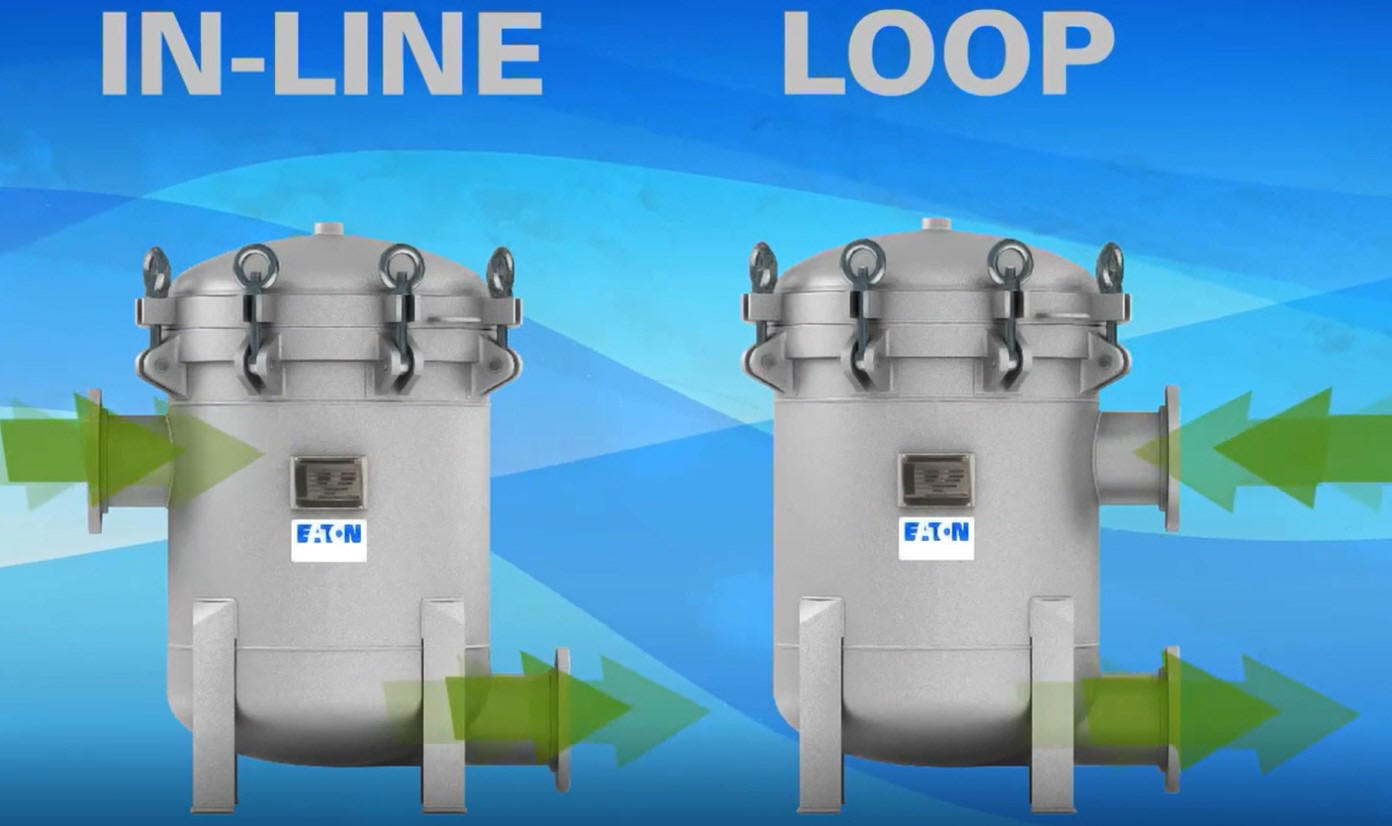

PROLINE bag filter housings are made of 304

stainless steel in both in-line and loop flow path configurations.

Both MAXILINE and PROLINE bag filters have their outlet nozzle mounted

tangentially to the dish shaped bottom, minimizing the vessel height in

support of comfortable ergonomics and reduced risk of injury when removing

full filter bags because ladders and stools are not required.

They also both have a swing eyebolt closure

(rated for pressures up to 150 PSIG at 200°F.), enabling quick access to the

filter bags, generally within 1-2 minutes, and provides a firm seal with

minimal effort. The spring assisted counter weight closure of both

MAXILINE and PROLINE enable one handed opening and it remains at any

position for safer access to the filter bag chamber.

PROLINE bag filters are compatible with industry

standard #2 size filter bags and a three-point hold-down ring ensures

positive downward sealing of the filter bag to the restrainer basket.

Both PROLINE and MAXILINE bag filters can be used

in conjunction with displacement balloons, filter bag positioners and

magnetic bars.

The special features of MAXILINE bag filter

vessels include additional materials of construction, quick-opening clamp

style covers and higher flow rates.

MAXILINE bag filter vessels are available in

carbon steel, 304 SS and 316SS as well as more exotic materials for

aggressive liquids. The MAXLINE bag filter vessels can have up to (24)

#2 size bag filter chambers in support of flow rates of approximately 3,170

GPM of water-like liquids filtered with nominally rated filter bags.

Due to the way they are manufactured, MAXILINE bag filters can have an ASME

U-code stamp if that is required for your application.

The MAXILINE series consists of (5) models, each

having a specific type of closure as dictated by the requirements of your

application. As with PROLINE vessels, MAXILINE bag filter vessels are

available with Buna-N, EPDM, Viton or Teflon o-rings.

The MAXILINE HD has a swing bolt closure lifted

by a hand wheel driven lifting davit, a requirement for filter housings

having 14+ filter bag chambers because the closure for housings that large

is too heavy for spring assisted hinged closures used by the other vessels.

Available in both 304 SS and carbon steel materials, its custom fabricated

design enables customizations such as oversized inlet/outlet nozzles.

The MAXILINE HE has a swing bolt closure but

instead of a lifting davit it has the aforementioned counter weighted spring

assisted hinged cover which self-balances such that at any position it

remains where you leave it; a safety feature to prevent the chamber cover

from falling onto an employee. The MAXILINE HE hinged style can only

be used for housings with up to eight filter bag chambers because the covers

for larger units are too heavy.

MAXILINE SE has a quick-opening closure; instead of swing bolts, it has a

clamp style open/closed by a manually operated hand wheel. To actuate the

hand wheel the operator must first disengage the vent valve, a safety feature to

ensure the vessel is depressurized prior to opening the cover. Eaton refers to

this as their Qic-Lock™ closure and it is specifically engineered to reduce both

the access time and risk of injury to personnel. As with the other

designs, the counter weighted spring assisted hinge simplifies access to the

filter housings 3 to 12 chambers.

The other two MAXILINE variations have chamber covers designed to seal

directly against the filter bag sealing ring, improving the sealing efficiency

for applications requiring 95%+ efficient retention of particles 25 microns and

smaller. These variations both have counter weighted spring assisted

hinged chamber covers, one having a swing bolt (MDE), the other with Qic-Lock™

style closure (VMDE).

Filter housing selection process

The first step is reviewing the flow rate requirements corrected for both

viscosity and intended particle retention size to determine the number of filter

bag chambers required; if it exceeds (12) then the only option we offer is the

MAXILINE HD.

The next criteria to consider is the fineness of filtration required and

whether the filter bag required has a specific >95% efficiency or if it is a

common, nominally rated design. High efficiency applications require the

crush seal style SENTINEL RING™ and benefit immensely from a filter bag closure

whose cover seals directly against the filter bag, the MAXILINE MDE or VMDE.

Nominally rated filter bag applications can be satisfied with one of the

other PROLINE or MAXILINE vessels based upon the aforementioned

characteristics. The next time you have a filtration application reach out to us

and we will put our experience to work for you!