This article compares two options for continuously filtering with bag filters, the Moduline and Duplexed Maxiline-HE bag filter systems. Eaton’s filtration division offers industrial filtration equipment for a broad range of applications. Their bag filter product line is typically used for relatively fine, high efficiency filtration applications. There are at least (2) filter bag sizes considered “industry standards”, meaning that these sizes are also offered by several of Eaton’s competitors. The largest “standard” filter bag is referred to as a #2 size and has a 7” diameter opening and is 32” long. Such filter bags are limited to a maximum flow rate of approximately 180 GPM and it could be much less for high efficiency, low micron retention filter bags. There are many high flow rate filtration applications which exceed the maximum flow rate through a #2 size filter bag and generally manufacturers like Eaton offer housings which hold multiple filter bags, up to 24 per vessel, to handle high flow rate, high particle loading or high viscosity applications.

Uninterrupted Flow

The most common and easiest to understand way to support continuous filtration is to use (2) filter housings operated in duplex. One filter housing is filtering the liquid while the other has new media and is ready for use. When the filter bags in the first vessel need to be changed, flow is diverted to the clean vessel and the vessel containing the dirty filter bags is isolated. Personnel can replace the filter bags and prepare it to be put into service again. Theoretically any size bag filter can be installed in a duplex configuration, all you need are large enough valves and sufficient space for the piping.

Eaton offers duplexed configurations of

their Maxiline-HE-T for vessels containing up to (8) #2 size filter

bags, approximately equivalent to 1440 GPM of water-like viscosity

liquid when using nominally rated filter bags. Flow can be increased

to about 1728 GPM when using proprietary HAYFLOW design filter bags.

These 8 chamber filter housings have 8” 150# ANSI flanged

connections.

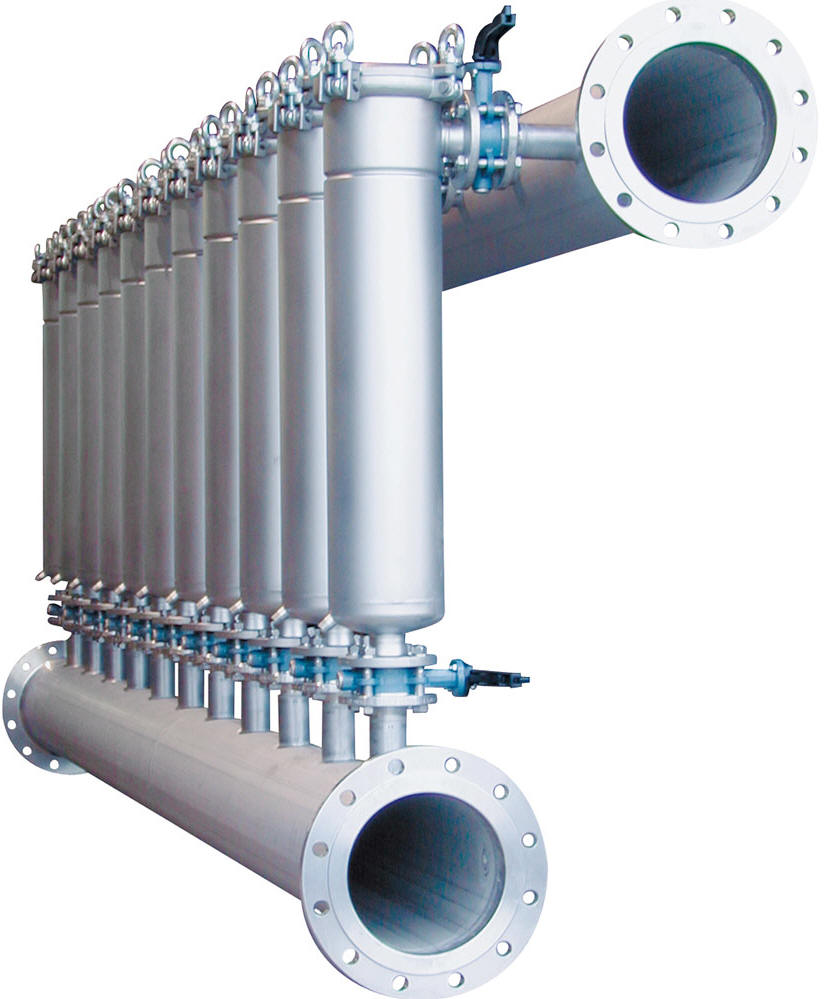

Another way of configuring multiple

filter bags for higher flow rate applications is installing multiple

bag filters vessels onto common inlet and outlet headers. Eaton

refers to this as their Moduline design and offers pre-assembled

filter skids consisting of (2) to (8) #2 size bag filter vessels.

While the maximum flow rate is the same

for both approaches, the Moduline enables continuous flow rates

without operating the filter housings in duplex. Instead, each

filter housing can be individually isolated for service, thus if you

configure your system to have 1 or more “extra” housings, you will

always have a clean vessel ready for service when you isolate a

vessel for bag changing. Theoretically nothing prevents a user from

installing (2) moduline’s in “duplex” nor are they limited to only

(8) housings. (8) housings and the required piping manifolds make

logistics sense from a pre-packaged and ready to ship design

perspective and you’ll notice how easy it is to simply connect

multiple units together in series. Likewise you can also install

multiple bag filter housings in series in support of very high flow

rates, but the purpose of this article is to compare two similar

“pre-packaged” designs consisting of (8) #2 filter bags.

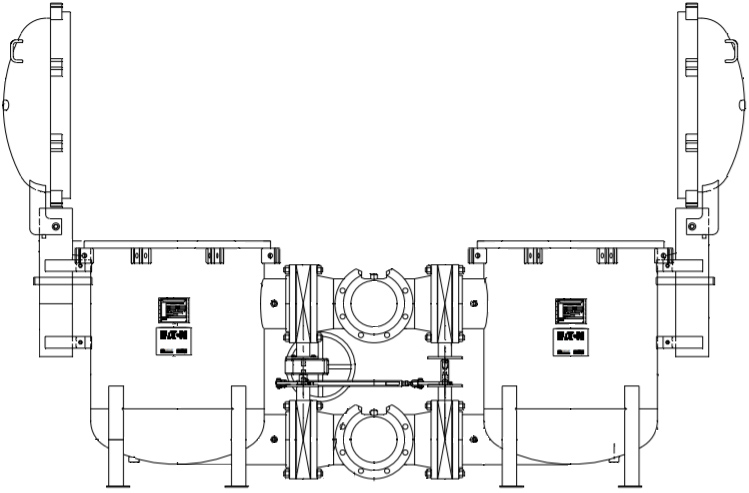

Maxiline HE-T Duplexed Bag Filter

Maxiline HE-T Duplexed Bag Filter

The specific features of the Maxiline HE-T are described in our articles How to choose a bag filter housing? and Comparison of PROLINE and MAXILINE Bag Filter Housings.

As the number of filter bag chambers increases, so does the difficulty of removing a filter bag filled with material. Each filter bag holds about 4.5 gallons, thus the weight of a fouled bag can easily exceed 40 lbs. It becomes increasingly difficult to reach over and lift up such bags over 32” high for clearance of the bag filter vessel.

The lower (outlet) manifold is connected

tangentially to the dished bottom specifically to reduce the vessel

height in support of improved ergonomics. Other features, such as

the hinged chamber cover make it easier for a single operator to

maintain the filter. You’ll notice that the orientation of the inlet

and outlet nozzles can be rotated as they are simply pipe tee

assemblies installed between a pair of isolation valves.

The lower (outlet) manifold is connected

tangentially to the dished bottom specifically to reduce the vessel

height in support of improved ergonomics. Other features, such as

the hinged chamber cover make it easier for a single operator to

maintain the filter. You’ll notice that the orientation of the inlet

and outlet nozzles can be rotated as they are simply pipe tee

assemblies installed between a pair of isolation valves.

The advantage of this design is that you can quickly access all filter bags. It has a small footprint for an 8-bag unit: 10’L x 3’W and the top of the filter bags are at about 46.5” with the unit itself needing about 80” to allow for the chamber cover to open.

The butterfly valves are interlinked for easy and safe diversion of flow and isolation of the chamber to be serviced.

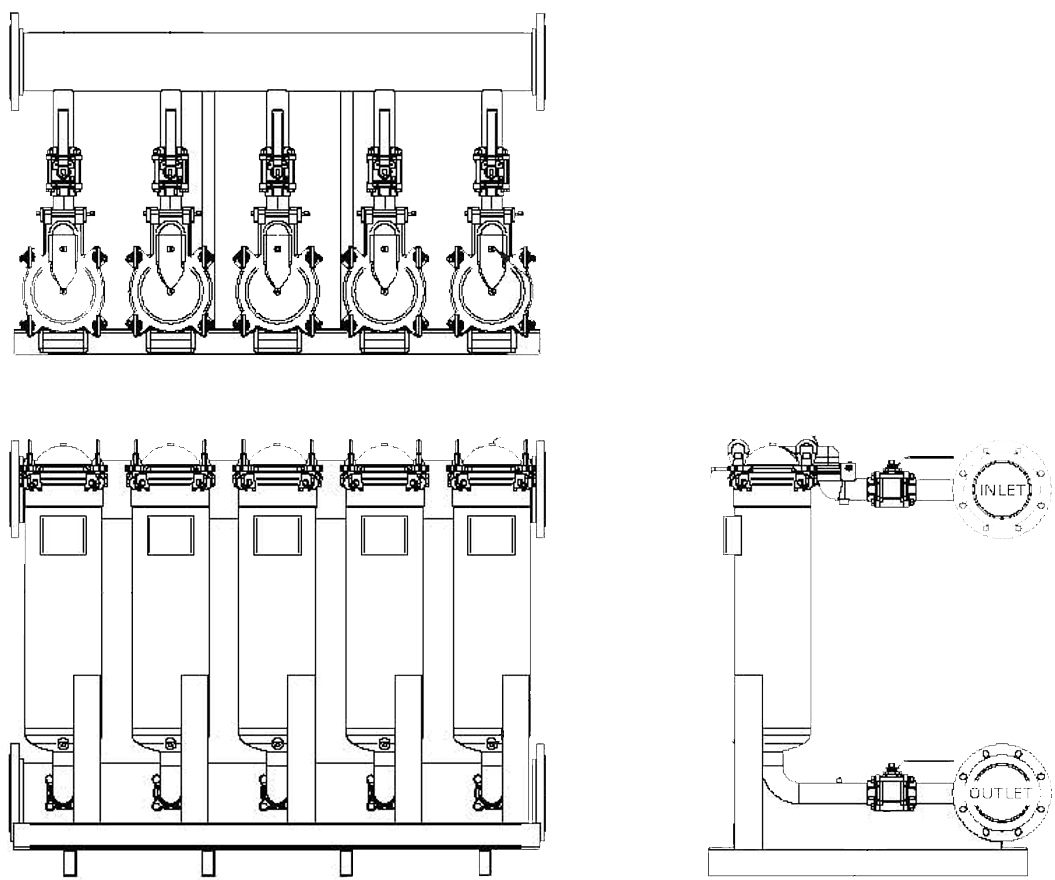

Moduline Bag Filter System

Moduline Bag Filter System

The modular approach with this design provides some flexibility for future expansion while maximizing ergonomics. As compared to the footprint of the duplexed 8 chamber Maxiline, the 8 chamber Moduline is only 8’ long by about 3’ wide and only requires about 52” of height to ensure the chamber cover can be opened – so its even more compact than the duplexed Maxiline.

When supplied as an assembly we can

account for “blank stations”; essentially plugged connections

enabling additional filter housings to be installed in the future if

needed. This isn’t something you can do with the multiple bag

housings because each filter bag chamber needs a corresponding

filter bag.

Which Design is Better?

Which Design is Better?

It is really tough

to say and has more to do with your specific operation. If you are

using nominal retention filter bags within the 50-to-800-micron

range, a Moduline can be provided for about the same cost as a

duplexed Maxiline, thus the choice is based upon footprint and

ergonomics. Some aspects of the Moduline can be customized, such as

automatic valve actuators, making it easier to safely take vessels

off-line and back into service. Both designs support use of magnetic

separators, high capacity HAYFLOW filter bags, displacement balloons

and high efficiency filter bag media.

While the Moduline design typically costs

more, it does enable customization by utilizing FLOWLINE II,

FLOWLINE, SIDELINE or TOPLINE style bag filter housings. It is also

easily expandable if required in the future. Its modular design

often means it ships quicker than duplexed Maxiline bag filter

housings.

It is quicker/easier to change-out all

the filter bags within a Maxiline bag filter housing because there

is only 1 chamber cover to open. There are closure designs which

automatically vent the vessel and unseal/reseal it by just rotating

a hand wheel (truly no tools required).

Eaton published an interesting article

illustrating how both Moduline and Maxiline (simplex) bag filter

housings were used in a single application for bowling ball

manufacturing (Eaton Rolls Out Winning Solution for Bowling Ball

Manufacturer)

The next time you have a challenging

filtration application let us put our 21 years of experience to work

for you!