Optimizing Filtration: Understanding How Liquid Viscosity Affects Filter Bag and Cartridge Applications

Filtration is an essential process across various

industries, serving to purify liquids and remove contaminants for downstream

applications. Choosing the right filtration method, whether using filter

bags or filter cartridges, is critical to achieving optimal performance. One

of the key factors influencing this decision is the viscosity of the liquid

being filtered, especially if it differs significantly from water. Viscosity

is a measure of a liquid's resistance to flow and thus impacts the

filtration process, including liquid velocity and differential pressure.

This article explains the relationship between liquid viscosity and

filtration, the advantages of filter bags or filter cartridges in different

scenarios, and some examples of common high and low viscosity liquids

filtered with filter bags and filter cartridges.

Understanding the

Impact of Liquid Viscosity on Filtration

Viscosity plays a fundamental

role in liquid filtration as it affects how the liquid flows through the

filter media. Liquids with higher viscosity have thicker and slower flows at

a given pressure, while low-viscosity liquids exhibit thinner and faster

flows at that same pressure. This difference in viscosity significantly

influences liquid velocity and differential pressure across the filter

media.

Liquid Velocity

In the context of liquid

filtration, liquid velocity refers to the speed at which the liquid flows

through the filter media. High-viscosity liquids experience reduced flow

velocities due to their inherent resistance. As these liquids traverse the

filter media, they must overcome the small pores and interstitial spaces,

resulting in slower movement and lower liquid velocities.

This is

problematic for both filter bag and filter cartridge filtration because it

can contribute to uneven flow distribution across the media. It can be

off-set somewhat by operating at a higher pressure and thus filter

cartridges might be a better choice due to their inherent ability to handle

higher differential pressures.

There are filter bag designs, such as

Eaton’s MAX-LOAD, which have comparable differential pressure ratings but

also offer the advantage of higher flow rate capacities and increased

surface area in support of less frequent media replacement and an overall

simpler housing design.

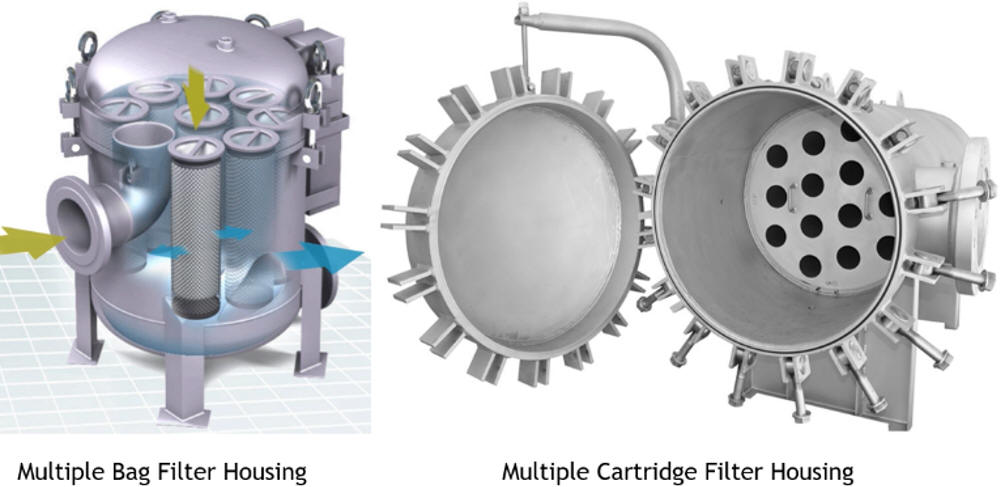

Bag filter housings are designed to

accommodate accessories which filter cartridge housings are not, namely

liquid displacement balloons and magnetic inserts. The displacement balloons

would help even-out the liquid distribution and for applications where

magnetic inserts are desired, the increased residence time amplifies their

effectiveness.

Differential Pressure

Differential pressure is the

pressure difference between the inlet and outlet sides of the filter.

High-viscosity liquids tend to generate higher differential pressures for a

given flow rate due to their increased resistance while passing through the

filter media. If the liquid is conveyed with a positive displacement pump

system, the flow rate will remain constant as the differential pressure

increases and the velocity through the filter media will increase as the

open area is reduced. Centrifugal pump and other fluid delivery systems may

deliver less flow with an increase in differential pressure, reducing the

liquid velocity and perhaps effecting the downstream process with the

reduced flow rate.

Filter Cartridges: Ideal for High Viscosity

Liquids

The high viscosity applications in which filter cartridges are

commonly used have a couple of characteristics besides higher differential

pressure tolerance that favor filter cartridge designs: lower flow rates and

necessity to retain finer solids.

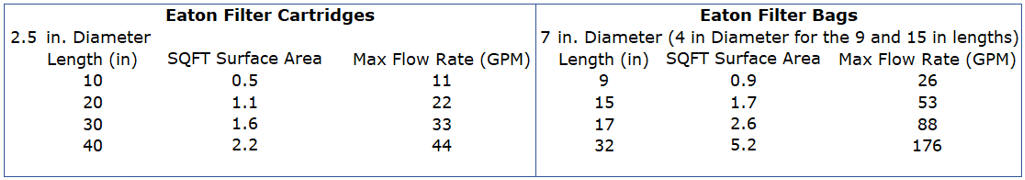

Single filter cartridge systems are limited in flow

rate to approximately 1 GPM per inch of length and the longest filter

cartridges offered through Eaton are 40” long. If the flow rate is

significantly higher than 40 GPM, it might be more cost effective to use a

single filter bag housing design compared to a multiple filter cartridge

design in terms of initial cost and ongoing cost related to media

replacement.

Filter bag designs that have similar maximum

differential pressure capabilities as filter cartridges are limited in their

filtration efficiency and size of particles which can be retained. Filter

cartridges tend to be more efficient and there are many designs for

submicron levels of filtration.

Therefore, if the flow rates are on

the higher end and a nominal >1 micron particle retention is required,

filter bags might be the most cost-effective solution whereas filter

cartridges provide more options for higher efficiency retention of finer

particle sizes and are especially cost effective for <40 GPM flow rate

applications.

Advantages of Filter Bags in Versatile Applications

While filter cartridges are advantageous in specific scenarios, filter bags

have advantages as well.

Larger Surface Area

Filter bags generally

have a larger surface area compared to individual filter cartridges. This

attribute makes them highly effective for filtering low to moderate

viscosity liquids. Thus, for the higher flow rate applications where

sufficient liquid velocity is available, the increased surface area

increases the duration between media replacement. This also contributes to

maintaining a lower differential pressure and perhaps a more consistent flow

rate.

Cost-Effectiveness

Filter bags are

typically less costly for high flow rate applications because filter

cartridge systems often require multiple cartridges to handle higher flow

rates which can be accommodated by a single filter bag. This is especially

true for applications which require nominal filtration efficiency of

particles >1 micron as the cost for complex filter bags with absolute rated

efficiency are quite expensive and more susceptible to damage via higher

differential pressures.

Specialized Accessories

Filter bag systems

offer various accessories, such as displacement balloons and magnetic

inserts, which can enhance filtration performance in specific applications.

Displacement balloons reduce the liquid retained within the filter bag and

inadvertently help maintain a higher velocity across the filter bag surface;

they reduce loss of process liquid due to media change-outs. Filter

cartridge systems generally retain less unfiltered liquid, so the addition

of displacement balloons to bag filter systems enable you to benefit from

the other aspects of filter bags while reducing loss of process liquid.

Magnetic separators are very powerful magnetic assemblies that reside

within the center of filter bags and they significantly increase the

retention efficiency of ferrous particles. Magnetic separators will extend

the duration between media changes for any liquids that contain high levels

of ferrous particles and benefit any application for which such metal fines

are problematic. There is no equivalent magnetic separation for industrial

filter cartridges.

Complexity and Cost Considerations

Higher flow

rate applications can be accommodated with a smaller filter vessel size and

use fewer filter units when using a filter bag housing. The inherent higher

capacity of filter bags (up to 4x the flow rate of the largest filter

cartridge offered by Eaton) results in less sealing points within the

vessel; the simplification of design lowers the cost of the vessel, and

contributes to less downtime for replacing clogged media.

Filter bags are often more cost effective than

filter cartridges, although there are less options for applications having

higher differential pressures or applications which require high efficiency

submicron particle retention.

Conclusion

Selecting the right

filter bag or filter cartridge style depends on the viscosity of the liquid

and the specific requirements of the filtration process. Filter cartridges

excel in handling higher viscosity liquids with elevated differential

pressures and finer solids, making them suitable for specific applications.

Certain models are designed to withstand higher liquid temperatures and

others are designed to mitigate fiber migration of the filter media itself.

On the other hand, filter bags offer larger surface areas and

cost-effectiveness, making them a versatile choice for most applications

involving low to moderate viscosity liquids. Understanding the impact of

liquid viscosity on filtration helps make informed decisions, ensuring

optimal filtration performance in diverse industrial settings. Whether it's

filter bags or filter cartridges, choosing the right filtration method is

crucial to achieving efficient and effective liquid purification.