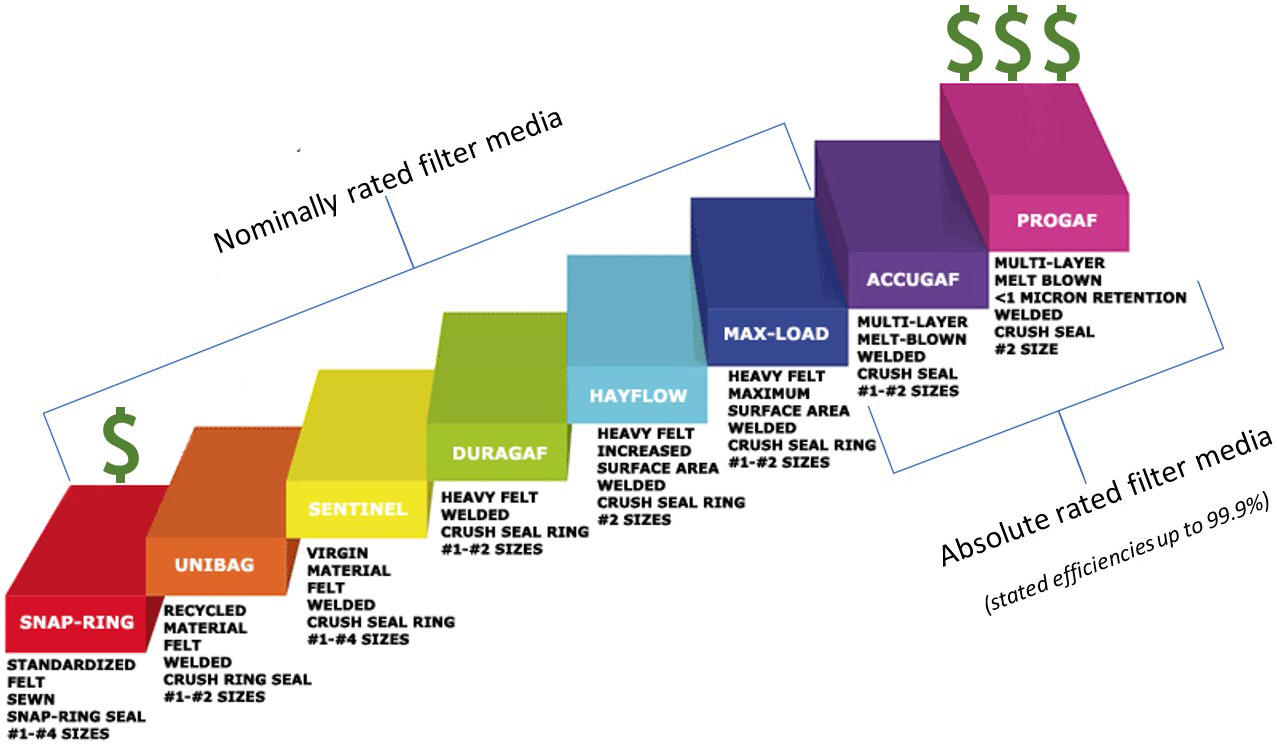

Comparison of Eaton Filter Bag Models

Snap-Ring, Unibag, Sentinel, Duragaf, Hayflow, Max-Load, Accugaf and Progaf

We make it easy to determine which filter bag model is best for your application and ensure quick delivery at the best cost by having the manufacturer drop-ship directly to you! Our filter bags are compatible with all #1-#4 size bag filter housing brands including Eaton, Hayward, GAF, American Felt, Loeffler, FSI, Tate Andale and Rosedale.

Once you have a bag filter system you also commit to the annual cost related to stocking, changing and disposing of filter bags. Our factory direct business model reduces your inventory requirements and our website explains features of our filter bags to help reduce the frequency of filter bag changes and improve personnel safety. The cost of a filter bag is directly related to its filtration efficiency and the amount of particles it can retain before requiring replacement. The following chart summarizes our product offering and our navigation menu provides details for each model.

Use our articles and webpages to learn about the features of

each filter bag model and then Call us at 908.362.9981 for factory direct pricing and

availability! Our sales engineers can assist with recommendations on the

phone or replying quickly to your emailed inquiry. Inquire about

receiving

free sample filter bags! If you aren't sure which filter

bag model best suits your application, use the navigation bar

beginning at "Start Here" and progressively go through the

selections.

Least Expensive Filter Bags

The

SNAP-RING and UNIBAG models are essentially the same in

terms of efficiency and cost, with the UNIBAG being made

from

recycled materials and having both a welded construction and

crush ring seal; characteristics of higher efficiency filter

bags. These are best suited for retention of particles

larger than 25 microns when the particle load is not too high.

All of the felt material filter bags provide a degree of

depth filtration although the SNAP-RING and UNIBAG models are made

of thinner material than the other filter bags, hence they

are used when the particle load for the targeted retention

size is relatively low. Monofilament and multifilament mesh

material SNAP-RING filter bags only provide

surface

filtration.

Industrial Performance Filter Bags

The SENTINEL and DURAGAF filter bags are made from thicker

felt material, increasing their depth filtration and overall

particle load retention. Before the UNIBAG, the

SENTINEL filter bag was the entry level filter bag to have a

welded seam and crush seal design. They are made from

virgin raw materials and this is our single most popular

style filter bag. DURAGAF filter bags are the same

except manufactured from even thicker felt and this

increases the particle handling capacity by 3 to 5 times!

DURAGAF filter bags cost about 2 times the cost of a

SENTINEL filter bag, however the annual cost savings

associated with filter bag changes off-set the higher filter

bag cost.

As an example, if you use 125 standard

filter bags monthly (1500 annually), the amount of DURAGAF

filter bags required might only be 300 - 500 annually. It

depends upon your operation but usually there are savings

associated with reduced filter bag changing, such

as:

-

Less labor

-

Reduced product loss due to carry-out

-

Increased safety for personnel due to less exposure to the liquid and less lifting

-

Less downtime

Special Filter Bag Designs

The balance of our filter bags have a specific purpose or characteristic. The HAYFLOW filter bag is clever design which requires a special restrainer (support) basket to utilize. HAYFLOW filter bags are made as a DURAGAF with about 70% more material, increasing the particle load handing capability. Another way of looking at this is that HAYFLOW filter bags increase your overall flow rate capacity due to the extra material used in their design. Therefore you would use this style filter bag when minimizing exposure to the liquid and reduced down time are priorities or when you have a high particle load and want to minimize the frequency of filter bag changes.

The MAX-LOAD filter bag is akin to a filter bag and filter cartridge hybrid with its pleated and rigid design, increasing surface area and maintaining its ideal shape. These are often used when the process liquid is hazardous and thus it is a priority to minimize exposure to personnel. If you have limited personnel and want to absolutely minimize the frequency of filter bag changes, MAX-LOAD filter bags are for you!

CLEARGAF, LOFCLEAR, ACCUGAF and PROGAF filter bags

These filter bags are used for specific types of applications and the most demanding, finest particle retention possible with filter bags. The CLEARGAF models are marketed for applications requiring FDA compliance and they are a nominally rated filter bag design based upon the SENTINEL and DURAGAF models.

LOFCLEAR, ACCUGAF and PROGAF filter bags are all absolute rated for their retention, meaning they have a specified efficiency up to 99.9% for the targeted particle size to be retained. They have a multi-layer design and complex crush seal ring to ensure zero bypass of particles as fine as 0.45 microns! The LOFCLEAR filter bags are used for automotive and other coatings applications sensitive to tramp oils. There is also a version designed for removing deformable, gel-like solids with an absolute retention efficiency.

ACCUGAF filter bags target particles from 1.5 to 10 microns with absolute efficiency whereas the PROGAF is used for 0.45 and 0.5 micron size particles; only the purest fluids and demanding applications require these types of filter bags.

Comparing Filter Bags

It is nearly

impossible to compare different brands of filter bags based upon

catalog pages alone because

each manufacturer uses different material thicknesses and fiber

size/density specifications. There is no universal

definition of "nominally efficient filter bags", each

manufacturer determines the acceptable range of efficiency

for a given filter bag design and therefore only the

absolute rated efficiency filter bags can be compared.

When you are switching filter bag manufacturers you want to

obtain some free sample filter bags to gauge their

efficiency compared to what you have been using. Our

nominally rated filter bags are more efficient than other

brands and it might be that instead of using a 10 micron bag

from manufacturer "X" our 25 micron filter bag might

suffice. An example of nominal efficiency and how it

can be confusing: a 1 micron nominally rated filter bag

might be 60-70% efficient for 1 micron and 99% efficient for

25 microns. Our filter bags specialists can help you

determine which style filter bag is best for your

application and investigate ways to minimize your costs.

Another factor to consider is product consistency. A large and

bureaucratic company like Eaton has well documented and tightly controlled

quality control procedures ensuring product consistency. Surely

distributors of filter bags can source from other countries and sell for less

cost, but much is not known about the quality control procedures used in

sourcing raw materials and manufacturing. In short, you get what you pay

for and if the pricing looks too good to be true, there’s likely a reason why.

Leverage Eaton’s resources and our decades of field experience to help you

determine which style filter bag is the best value for your application!

Accessories

We offer accessories to reduce product

loss and enhance personnel safety such as displacement

balloons, splash guards and magnetic inserts. These

items are often compatible with any brand filter housing and

their benefits work with your existing filter bags.

Due to our business model we offer very competitive pricing

enabling us to forge strong relationships with companies

worldwide. Please let us now how we can assist you further!