ACCUGAF™ FILTER BAGS

Absolute rated, BETA 5000 efficiency filter bags

![]() IOM manual for ACCUGAF, PROGAF

and LOFCLEAR

filter bags

IOM manual for ACCUGAF, PROGAF

and LOFCLEAR

filter bags

ACCUGAF

filter Bags are high performance, fully welded, melt-blown

hydrophobic microfiber filter bags manufactured from polypropylene or polyester.

The materials and manufacturing process are silicon-free and subject

to rigorous quality control proceedures per ISO 9001:2015 to ensure

consisitancy of each filter bag. The melt-blown manufacuring

process dos not require additives such as resins,

binders of surface treatments; only pure polypropylene or polyester

fibers. Essentially polymer is melted and spray atomized with

hot air to form filaments which are collected by a moving screen.

These fibers are further processed downstream with calendars

to produce specific densities and thicknesses.

ACCUGAF

filter Bags are high performance, fully welded, melt-blown

hydrophobic microfiber filter bags manufactured from polypropylene or polyester.

The materials and manufacturing process are silicon-free and subject

to rigorous quality control proceedures per ISO 9001:2015 to ensure

consisitancy of each filter bag. The melt-blown manufacuring

process dos not require additives such as resins,

binders of surface treatments; only pure polypropylene or polyester

fibers. Essentially polymer is melted and spray atomized with

hot air to form filaments which are collected by a moving screen.

These fibers are further processed downstream with calendars

to produce specific densities and thicknesses.

The fibers used to fabricate ACCUGAF filter bags are hydrophobic/oleophilic and therefore require pre-wetting with an aqueous solution as outlined in the ACCUGAF IOM manual. Polypropylene fibers naturally attract trace oils and thus they are also used for adsorption of oil. Each filer bag is individually sealed with a copy of the pre-wetting instructions.

The multi-layer ACCUGAF filter bag

design provides BETA 5000 (absolute 99.9%) particle

retention across a range of 1½ - 25 microns, each layer providing an increasingly

finer particle retention to maximize filtration efficiency

(prefilter, intermediate filter and final filter structure). The layered

design maximizes the particle holding capacity through ultra-efficient depth

filtration. Separate polypropylene cover layers prevent downstream

fiber migration. The

flexible SENTINEL crush style sealing ring

forms a seal that improves as the differential pressure increases,

ensuring particles do not bypass the filter bag. Integrally molded handles

within the sealing ring are easy to grab for bag removal.

The sealing ring and all seams are welded to maximize durabiltiy of the

filter bag.

All polypropylene materials used in manufacturing comply with the regulations of the Food and Drug Administration (FDA), title 21 of the Code of Federal Regulations Section 177, and EC Regulations 1935/2004 and EC Directive 2002/72/EC, as applicable for food and beverage contact.

Common ACCUGAF Filter Bag Applications:

-

Beer, wine, sprits and beverage filtration

-

Fine particle removal in parts cleaning processes

-

Final filtration of lacquers

-

Final filtration of vinegar

-

Removal of activated carbon

-

Filtration of hydraulic oils and lubricants

-

Electroplating

-

Magnetic coatings

-

Blood fractions

-

Cosemetics

-

Fermentation

-

Chemical and emulsions

-

Plastics manufacturing

-

Water treatment

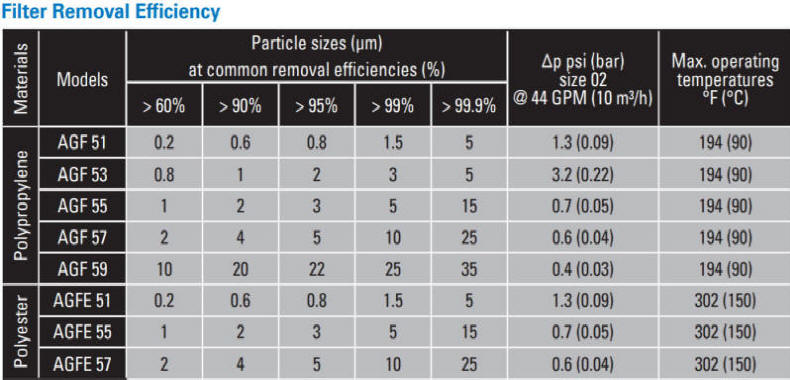

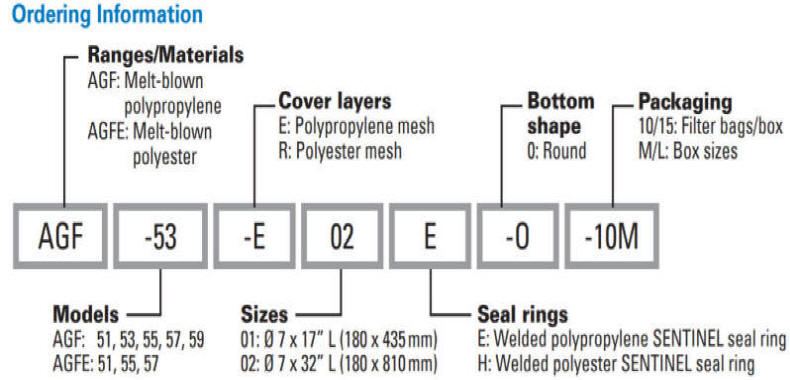

ACCUGAF filter bag specifications:

-

#1 size ACCUGAF bags have 2.6ft2 of filter area and are 7" diameter x 17" long

-

#2 size ACCUGAF bags have 5.2ft2 of filter area and are 7" diameter x 32" long

-

Maximum temperature ratings:

-

194ºF for polypropylene material

-

302ºF for polyester material

-

-

Maximum differential pressure of 36 PSI

-

Recommended replacement differential pressure between 11.6 - 21.7 PSI

-

-

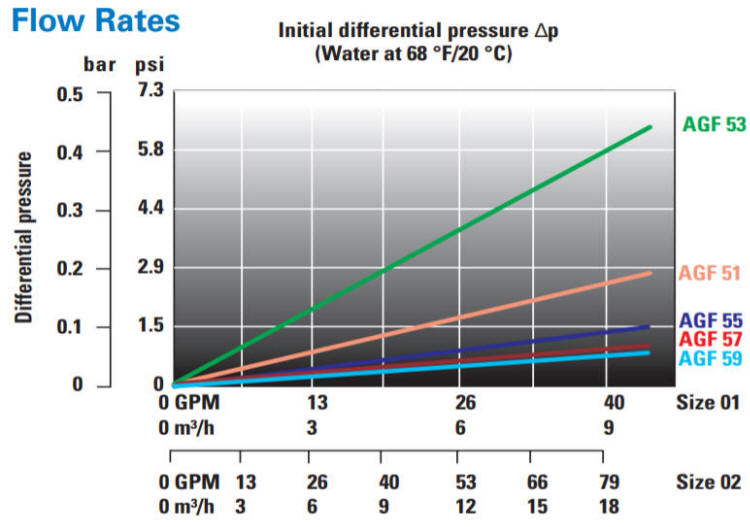

Maximum flow rates:

-

#1 size ACCUGAF bags, 35 GPM

-

#2 size ACCUGAF bags, 66 GPM

-

ACCUGAF filter Bags ship within 72 hours when in-stock and may require up to 8 weeks when not in-stock; it depends upon where the factory is in the stock replenishment cycle. We can allocate reserve inventory for your company to support JIT deliveries. If lead time is critical please contact us and we'll provide a firm readiness to ship date.