Filter Bag Accessories

Improve filtration Efficiency with these items

There are several accessories for use in bag filter housings which will improve filtration efficiency, reduce costs and improve safety. Some items, such as restrainer baskets and hold-down rings come with a bag filter housing and others (bag positioners, magnetic separators, displacement balloons and splash guards) contribute to less product loss, longer filter bag life and a safer work environment.

Restrainer (support) Basket

Restrainer (support) Basket

All bag filter housings have a restrainer basket for each

filter bag chamber. The filter bag is inserted into the

support basket and positioned so that it is unfolded and open as

much as possible. The physical shape of the basket, whether it

has a flat bottom as pictured or a conical bottom does not affect

its main purpose, which is to fully support the filter bag.

Once a filter bag is clogged with particles, a significant amount of

process liquid will also be retained. The support basket

reduces the stress on the filter bag seams because it is a few

inches shorter then the actual filter bag. This physical

support helps keep the filter bag intact when removing it from the

bag filter housing. The standard

design has 9/64" perforations and is made of 316SS. We also

offer mesh lined versions to "convert" filter housings into large

pipeline strainers. For coarse filtration applications this

may be a better alternative than mesh filter bags. The

advantage to using a bag filter housing for <4" pipelines is the

ability to handle higher flow rates as the open area ratio is

significantly higher due to the elongated bag filter body.

Additionally the mesh lined baskets can be cleaned and reused. We can

supply

replacement or spare support baskets

for any brand bag filter housing.

Hold Down Ring

These

are required for filter bags having a crush ring style seal by ensuring

the seal between the filter bag and housing is tight enough to prevent

particles from bypassing the filter bag. The hold down ring is

compressed between the filter housing cover and the support basket; its springy

handle will ensure a positive

concentric seal against the filter bag support basket (restrainer

basket). Multiple chamber bag filter housing designs use a

different style hold down ring, it locks in-place against the support

basket and does not have a protruding handle. Hold down rings are

not required for SNAP-RING™ filter bags. If the handle becomes

damaged such that downwards pressure is inadequate it will increase the

potential for particles to bypass the filter bag.

Sometimes referred to as "filter bag locks", these

ensure proper positioning of the filter bag within the restrainer

(support) basket. While the support basket provides filter bag

support from high differential pressure, filter bag positioners provide

support in systems having a high back-pressure. Higher pressure

applications and the potential for hydraulic shock can cause movement of

the filter bag, essentially stressing its seams in a different direction. Bag positioners should be used for

all applications that have potential for back pressure and water

hammer. They are a requirement for melt-blown filter bags having

welded seams (ACCUGAF™,

PROGAF™

and LOFCLEAR™).

These

are required for filter bags having a crush ring style seal by ensuring

the seal between the filter bag and housing is tight enough to prevent

particles from bypassing the filter bag. The hold down ring is

compressed between the filter housing cover and the support basket; its springy

handle will ensure a positive

concentric seal against the filter bag support basket (restrainer

basket). Multiple chamber bag filter housing designs use a

different style hold down ring, it locks in-place against the support

basket and does not have a protruding handle. Hold down rings are

not required for SNAP-RING™ filter bags. If the handle becomes

damaged such that downwards pressure is inadequate it will increase the

potential for particles to bypass the filter bag.

Sometimes referred to as "filter bag locks", these

ensure proper positioning of the filter bag within the restrainer

(support) basket. While the support basket provides filter bag

support from high differential pressure, filter bag positioners provide

support in systems having a high back-pressure. Higher pressure

applications and the potential for hydraulic shock can cause movement of

the filter bag, essentially stressing its seams in a different direction. Bag positioners should be used for

all applications that have potential for back pressure and water

hammer. They are a requirement for melt-blown filter bags having

welded seams (ACCUGAF™,

PROGAF™

and LOFCLEAR™).

Bag

Positioner

Bag

Positioner

Sometimes referred to as "filter bag locks", these ensure proper positioning of the filter bag within the restrainer (support) basket. While the support basket provides filter bag support from high differential pressure, filter bag positioners provide support in systems having a high back-pressure. Higher pressure applications and the potential for hydraulic shock can cause movement of the filter bag, essentially stressing its seams in a different direction. Bag positioners should be used for all applications that have potential for back pressure and water hammer. They are a requirement for melt-blown filter bags having welded seams (ACCUGAF™, PROGAF™ and LOFCLEAR™).

Magnetic Separators

This refers to one or more stainless steel encapsulated magnets installed within the filter bag. Magnetic separators create a powerful magnetic field and need to be centered within the filter bag with a modified bag positioner. These (2000 - 9300 G) rare earth magnetic assemblies will prevent most ferrous particles from contacting the filter bag and therefore extend the time between filter bag changes. Magnetic separators also concentrate the ferrous materials in support of recycling programs. We have written an article describing the benefits of magnetism called Augmenting Filtration with Magnetism.

Displacement

Balloons

Displacement

Balloons

These are a hollow cylinder having a handle and it is another type of bag positioner. The cage style bag positioner pictured above only helps spread-out the filter bag and reduce its movement due to downstream back pressure. Displacement balloons have the same effect except they also displace the volume of liquid within the filter bag. The overall differential pressure is not affected because the displacement balloon is suspended within the center of the filter bag, thus the restriction to flow is only the filter bag itself. When it is time to change the filter bag, the balloon is lifted from the vessel and the remaining amount of process liquid is minimal. With a #2 size filter bag product loss due to carry-out can be as high as 4.5 gallons and with a displacement balloon only about 0.5 gallons. In addition to saving process liquid, personnel are less likely to be directly exposed to the liquid and lifting the support basket with clogged filter bag is much lighter - a significant improvement in ergonomics.

This is a safety accessory engineered for FLOWLINE and FLOWLINEII bag filter housings to protect the eyes and faces of operators from unexpected pressurized spray and "splash" of the filtered fluid. A broken or misplaced seal, a spike in line pressure, or the failure to fully relieve system pressure before servicing the filter bag vessel can result in potentially dangerous and costly spray. The Splash Guard deflects the spray downwards and away from the faces of personnel.

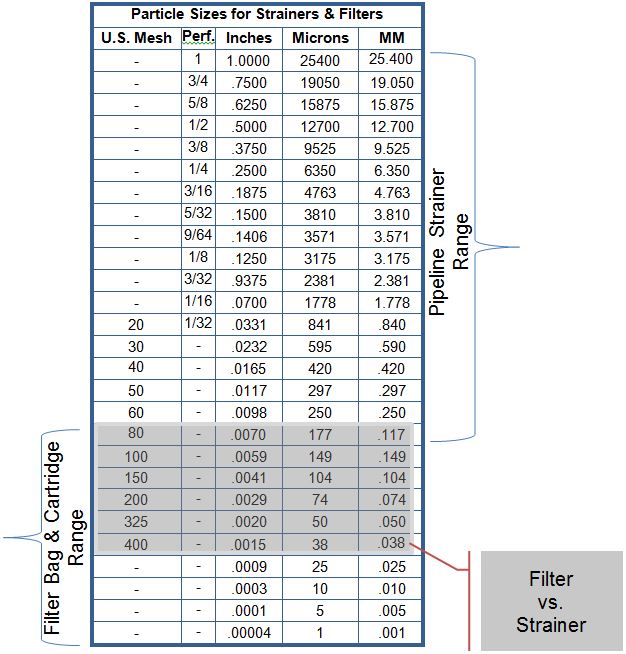

PARTICLE SIZE CONVERSION CHART