LOFCLEAR™ 100 SERIES FILTER BAGS

99% efficient filter bags for partcle retention sizes from 4 to 40 microns

![]() LOFCLEAR™ 100 Series Specification Sheet

LOFCLEAR™ 100 Series Specification Sheet

LOFCLEAR

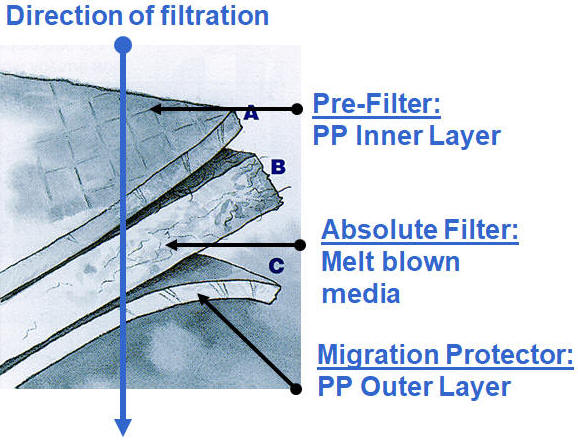

high performance filter bags are used for demanding particle removal

applications. LOFCLEAR filter bags have a three layer design

to provide BETA 100 (99%) efficiency for retaining particles from 4

to 40 microns. Constructed entirely of polypropylene, each

layer is sewn together and molded to the crush style sealing ring.

The first layer retains larger particles and creates a flow path

into the depth filtration layer. The final layer, made from

spunbound polypropylene, prevents fiber migration.

LOFCLEAR

high performance filter bags are used for demanding particle removal

applications. LOFCLEAR filter bags have a three layer design

to provide BETA 100 (99%) efficiency for retaining particles from 4

to 40 microns. Constructed entirely of polypropylene, each

layer is sewn together and molded to the crush style sealing ring.

The first layer retains larger particles and creates a flow path

into the depth filtration layer. The final layer, made from

spunbound polypropylene, prevents fiber migration.

The filter layers are made of melt-blown polypropylene with a process that does not require lubricants to ensure they are free from silicone and crater-forming substances. The manufacturing facility has tough quality control proceedures (ISO 9001:2015) to guarantee both performance and product consistancy.

The crush seal filter bag ring welded to each layer of the filter bag creates a by-pass free seal against the support basket and bag filter housing.

LOFCLEAR filter bags are used for filtation of high purity fluids having low particle concentration, removal of gelentious particles and oil adsorption due to the pure melt-blown polypropylene fibers contained in each layer. The geometry of each layer breaks-up gelatinous particles and they become embedded within the depth of the filter media.

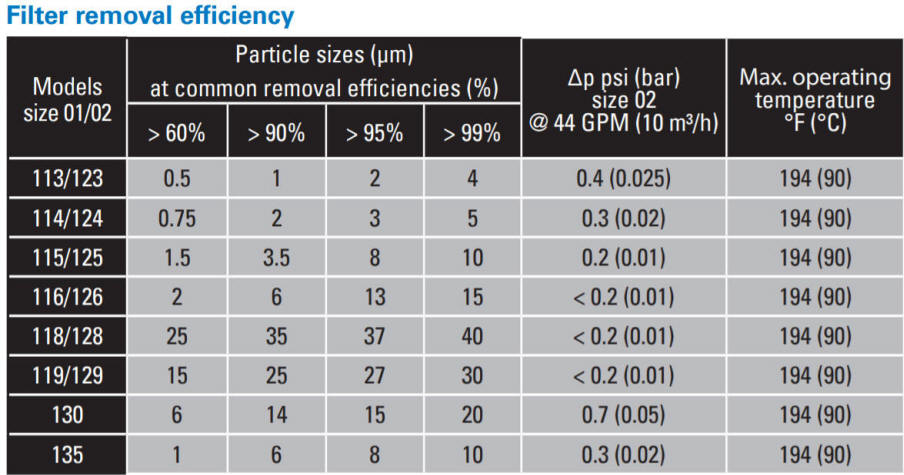

Specifications:

-

#1 (7" diameter x 17" long) and #2 (7" diameter x 32" long) sizes are available

-

#1 size LOFCLEAR filter bags have 2.6ft2 of filter area

-

#2 size LOFCLEAR filter bags have 5.2ft2 of filter area

-

-

Maximum temperature rating is 194ºF for polypropylene material

-

Maximum differential pressure of 36.2 PSI

-

Recommended replacement differential pressure between 11.6 - 21.7 PSI

-

-

Maximum flow rates:

-

#1 size LOFCLEAR filter bags, 35 GPM

-

#2 size LOFCLEAR filter bags, 66 GPM

-