Modern technology has resulted in a proliferation of filter bag designs,

but unfortunately they all tend to look similar and pricing is often a major

factor in the decision process – but that might be shortsighted and increasing

operational costs.

Filter bags are installed within filter housings, a pressure vessel that

directs the process flow through the filter media to remove unwanted particles.

Filter bags are designed to be thrown away after use, attempting to clean and

reuse them is not recommended. The “cost” of a filter bag begins with the media

itself but also involves the frequency of filter bag changes and the annual

disposal costs. It is the frequency of changing and perhaps reduced

quantity of filter bags required annually that often contributes most to

reduction in operational costs.

Filter Bag Designs

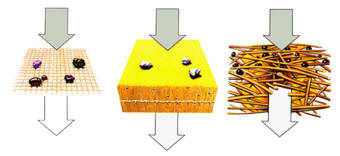

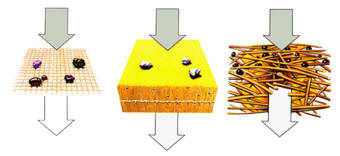

The physical structure of filter bags fall into three categories, mesh,

needle-felt and melt-blown. The manufacturing technique for each category

determines the materials of construction that can be used.

The physical structure of filter bags fall into three categories, mesh,

needle-felt and melt-blown. The manufacturing technique for each category

determines the materials of construction that can be used.

Needle-felt filter bags are generally the least expensive style and are

the most common with mesh styles being a little more expensive mostly due to the

materials compatible with the required manufacturing process. Melt-blown

and multi-layered filter bags are the most expensive but also provide higher

efficiencies.

Filter Bag Sealing Rings

In addition to the material and manufacturing process, filter bags have a

sealing ring designed to prevent particulates from bypassing the material.

The sealing ring thus provides a seal between the filter bag and the vessel.

The most common sealing ring designs are a “snap-ring” and a “crush-seal ring”.

In addition to the material and manufacturing process, filter bags have a

sealing ring designed to prevent particulates from bypassing the material.

The sealing ring thus provides a seal between the filter bag and the vessel.

The most common sealing ring designs are a “snap-ring” and a “crush-seal ring”.

A snap-ring is a metal or plastic ring sewn within the opening of the

filter bag, which aligns with a groove within the filter bag housing.

Based upon the tolerance of the groove and ring, the filter bag is held firmly

in-place yet can be removed by hand for change-outs; filter bags have handles to

grab so they can be lifted from the vessel.

A crush-seal ring is a geometrical shaped plastic ring that also has an

outer diameter that “snaps” into the support basket groove. Sealing is

further enhanced by downwards pressure onto the top of the sealing ring, which

creates an outward force and improving the seal between the ring and sealing

grove. The downwards pressure is achieved by the filter vessel cover,

either directly or via a hold-down ring to transmit the downwards force of a

closed chamber cover to the top of the filter bag.

A crush-seal ring is a geometrical shaped plastic ring that also has an

outer diameter that “snaps” into the support basket groove. Sealing is

further enhanced by downwards pressure onto the top of the sealing ring, which

creates an outward force and improving the seal between the ring and sealing

grove. The downwards pressure is achieved by the filter vessel cover,

either directly or via a hold-down ring to transmit the downwards force of a

closed chamber cover to the top of the filter bag.

Filter Bag Efficiency

Filter bag retention is referred to as being nominal or absolute.

Nominal in this context essentially means “approximately” whereas absolute is

related to a specified efficiency. Higher efficiency filter bags are more

complex and expensive therefore generally reserved for the most demanding

applications.

There is no industry standard relating “nominal” to a specific efficiency;

each manufacturer determines the acceptable range of efficiency and thus it

is necessary to compare filter bag performance and NOT rely on the stated

nominal retention.

The efficiency for our nominally rated filter bags tends to be 65-70% and

I am told that some manufacturers reduce costs by accepting lower efficiencies,

so “you get what you pay for” applies to filter bags as most other things in

life.

SNAP-RING®

Although also an accurate description of the seal type and generically

referred to as “snap-ring” it is also a registered trademark owned by Eaton

Hydraulics, Filtration Division LLC. These represent their inexpensive

line of filter bags, offered in polyester, polypropylene, nylon, nomex and PTFE

felt materials. The rings sewn into the filter bag openings are zinc

plated steel, 316SS or polypropylene.

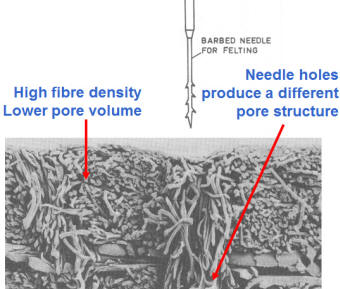

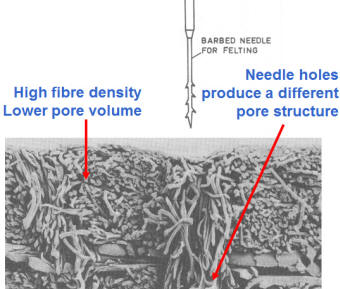

SNAP-RING® filter bags have a sewn construction. A web of

material is perforated with a needle board to create the holes determining

retention and one side is singed to reduce the change of fibers “migrating”

downstream.

Materials are mass produced by mills and tested for their retention

efficiencies, then sold to companies which manufacture filter bags.

SNAP-RING® filter bags have a nominally rated efficiency. Although

offered in 1, 5, 10 and 25 micron sizes, the limitations of a snap-ring seal

with the sewn construction makes them best for 50+ micron retention

applications.

The material is relatively thin and thus they primarily provide surface

filtration and require replacement more frequently than filter bags made with

heavier materials providing depth filtration.

The snap-ring style filter bags are also available in woven materials such

as nylon, essentially weaving single or multi-filament polymeric threads into a

single layer grid-like pattern. The manufacturing process and materials are more

expensive than needle felt filter bags and they still have nominally rated

retention efficiencies because the spacing, angle of weave and stabilization of

the mesh grid are difficult to control.

Crush-Seal Ring Filter Bags

Eaton’s refers to this style of sealing ring as being a SENTINEL®

ring and they offer seven filter bag designs having this enhanced seal design.

SENTINEL®

The original filter bag designed with the crush-ring style is actually

called a SENTINEL® filter bag. Like the snap-ring filter bags

above, these are made of needle-felt materials (polyester or polypropylene) and

their sealing rings are made of polyester or polypropylene also.

SENTINEL® filter bags have nominally rated retentions, however

their sealing ring design and having a welded seam instead of a sewn seam

increases their relative efficiency and strength when compared to snap-ring

style filter bags.

A version of this bag, referred to as the UNIBAG® is

made from recycled materials to support “green” products and they are less

expensive than snap-ring style filter bags.

As with the snap-ring style filter bags, the crush-ring style can be

applied to mesh design filter bags.

Premium Efficient Filer Bags

Premium Efficient Filer Bags

The

DURAGAF® filter bag design can retain more

particulate due to its thicker material and complexity of design. Although

this style costs more, it also typically lasts at least 3 times as long as

needle-felt filter bags, so this is where operational savings kick-in.

Remember that fewer changes equate to reduced:

Employing a melt-blown manufacturing process, the fibers used have a

smaller diameter and are less likely to “migrate” downstream. The melt-blown

process provides control over the material density and thickness.

Polypropylene, polyester and nylon can all be manufactured with a melt-blown

process.

Employing a melt-blown manufacturing process, the fibers used have a

smaller diameter and are less likely to “migrate” downstream. The melt-blown

process provides control over the material density and thickness.

Polypropylene, polyester and nylon can all be manufactured with a melt-blown

process.

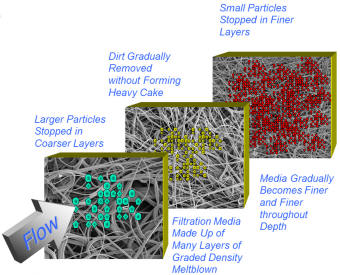

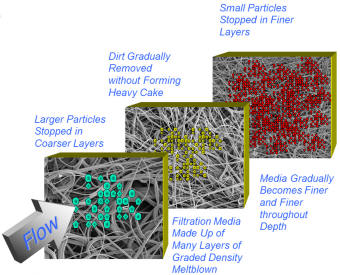

ACCUGAF® filter bags have absolute rated

efficiencies and consist of multiple layers of melt-blown polypropylene.

The well documented efficiencies results from the multi-layer approach;

the coarser materials remove larger particles and the increasingly finer layers

remove finer particles. Relying on multiple layers also ensures purity of

materials as no binders or additives are required for formulating a single

complex layer/structure.

PROGAF® filter bags represent the most

complex design available, having efficiencies, which rival filter cartridges

while providing holding capacities and supporting flow rates that would require

a multiple cartridge housing design.

The premium efficiency stems from the number of layers and a modified

crush-seal ring which is welded to each layer to ensure a specific flow path.

Variations

The

LOFCLEAR® model represents a special purpose

multi-layer design to adsorb trace oils and entrap gelatinous/deformable

particles, mostly for critical coating applications.

The

HAYFLOW™ design offers greater surface area; its needle-felt

material with crush-ring is “doubled-up” within the filter bag housing to

support increased particulate loading and higher flow rates.

Choosing the Right Filter Bag

Physical Size

Thankfully almost all filter bag housing manufacturers offer housings for

#1 - #4 size filter bags, the most common being #1 and #2 sizes (having a 7”

diameter opening and 16” or 32” length). The filter bag size will begin to limit

your options if its anything other than a #2 size.

Efficiency

Most applications use nominally rated efficiency filter bags; this aspect

of your application will further narrow-down what is available to you.

Materials of Construction

Chemical and temperature compatibility with your fluid is another

important consideration. Some materials are considered FDA compliant,

meaning the manufacturing process and materials used satisfy FDA requirements.

You need to choose a material which will last and contribute to product quality.

Guidelines

Needle-felt materials provide a limited amount of depth filtration and

represent the majority of the filter bag market. They are used for 1 to

200 micron nominal retentions and are the least expensive (unit cost) design

available.

Melt-blown materials are ideal for ½ to 25 micron retentions, nominal or

absolute efficiencies, provide increased depth filtration and thus typically are

not replaced as often.

Mesh materials are best for solid particles and can be gently cleaned in

some cases for re-use; these are typically used for larger size particle

retention, >100 microns (nominally rated).

Accessories

Filter bag positioners, displacement balloons and magnetic inserts enhance

certain filtration applications.

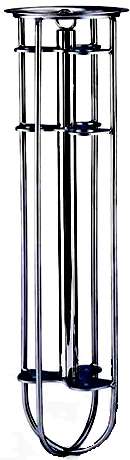

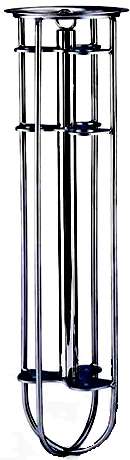

Filter Bag Positioners are cage-like structures that limit the movement of

the filter bag and thus help prevent damage due to pressure spikes related to

fast acting valves within a piping system.

The displacement balloon variation goes one-step further, displacing the

majority of the volume within the filter bag to reduce product loss during

filter bag changes; consequentially the filter bags are lighter and easier to

remove, reducing chance of personnel injury.

Using 9300 Gauss rare earth magnet assemblies within a bag positioner

increases the efficiency and retention capacity of magnetic particles.

Let Us Help! call 908.362.9981

and speak with a factory trained filter bag specialist

Our primary function is to assist you by providing you with the best

product for your application, so you do not need to become an expert in “filter

bags”; leverage our experience by letting us know about the important aspects of

your application and we’ll make some suggestions. We can provide you with

free samples for testing and a detailed particulate analysis in support of

properly sizing a bag filter vessel or choosing the most appropriate filter bag

design - AT NO CHARGE. All we need is a sample of the fluid to be filtered

and up to 2 weeks for the analysis and report to be generated.

Our website

is a great starting point to not only learn about all of our filter bag

products, but it also streamlines the information gathering process with custom

inquiry forms for filter bags, sample filter bags and fluid testing.

The physical structure of filter bags fall into three categories, mesh,

needle-felt and melt-blown. The manufacturing technique for each category

determines the materials of construction that can be used.

The physical structure of filter bags fall into three categories, mesh,

needle-felt and melt-blown. The manufacturing technique for each category

determines the materials of construction that can be used.

In addition to the material and manufacturing process, filter bags have a

sealing ring designed to prevent particulates from bypassing the material.

The sealing ring thus provides a seal between the filter bag and the vessel.

The most common sealing ring designs are a “snap-ring” and a “crush-seal ring”.

In addition to the material and manufacturing process, filter bags have a

sealing ring designed to prevent particulates from bypassing the material.

The sealing ring thus provides a seal between the filter bag and the vessel.

The most common sealing ring designs are a “snap-ring” and a “crush-seal ring”.

Premium Efficient Filer Bags

Premium Efficient Filer Bags Employing a melt-blown manufacturing process, the fibers used have a

smaller diameter and are less likely to “migrate” downstream. The melt-blown

process provides control over the material density and thickness.

Polypropylene, polyester and nylon can all be manufactured with a melt-blown

process.

Employing a melt-blown manufacturing process, the fibers used have a

smaller diameter and are less likely to “migrate” downstream. The melt-blown

process provides control over the material density and thickness.

Polypropylene, polyester and nylon can all be manufactured with a melt-blown

process.