MELT BLOWN FILTER CARTRIDGES

LOFTREX™ melt blown filter cartridges have a multi-density design to simultaneously retain both coarse and fine particles. The outer portion consists of non-woven melt blown polypropylene for retention of larger particles.

The inner area consists of an inner core made from bi-component polypropylene and polyethylene fibers, polypropylene, stainless steel or nylon depending upon the model.

Surfactants are not used in the manufacture of LOFTREX™ filter cartridges and they satisfy FDA CFR Title 21 requirements. LOFTREX™ filter cartridges are offered in four designs encompassing both nominal and absolute rated retentions and single and multi-zone designs for retentions within ½ to 150 μm.

What is a melt blown filter cartridge?

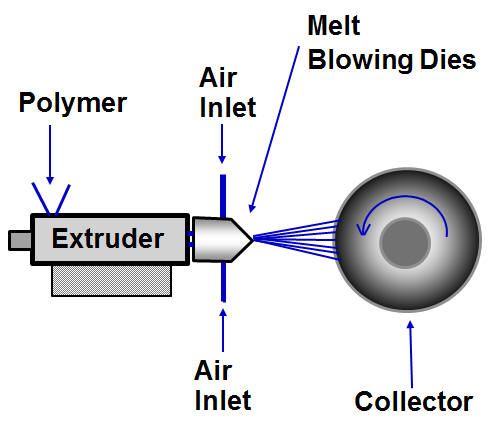

Melt blown filter cartridges are less expensive than pleated and membrane filter cartridges, therefore an economical choice for applications requiring frequent filter cartridge changes. They are made by heating-up polymers to a liquid state and then atomizing them with air to form strand-like filaments to form a cylindrical shaped filter cartridge. The resulting layer of fibers provides depth filtration as described in our article Depth Filtration vs. Surface Filtration.

CAT scan of melt blown Fibers

Cross section view of random density filter cartridge

Four Melt Blown Filter Cartridge Models

The LOFTREX™ filter cartridges are made from polypropylene microfibers with a coreless design and have a nominal retention rating of 80% efficiency. The LOFTREX-N is the same design except it is made from nylon (polyamide 6.6 ) fibers.

LOFTREX-M filter cartridges are made of polypropylene and have an inner support core made of polypropylene to nearly double its maximum differential pressure rating as compared to the LOFTREX™ and LOFTREX-N filter cartridges.

LOFTOP filter cartridges have an absolute rated retention efficiency of 99.98% (beta 5000) and an inner core made of polypropylene or stainless steel. The following chart provides a base comparison of our melt blown filter cartridges and has links to each specification page.

MELT BLOWN FILTER CARTRIDGE MODELS

| Model | Material | Efficiency | Maximum Differential Pressure |

Maximum Temperature |

| LOFTREX | Polypropylene | 80% | 35 PSI | 176ºF |

| LOFTREX-M | Polypropylene | 95% | 58 PSI | 176ºF |

| LOFTOP | Polypropylene | 99.98% | 35 PSI | 176ºF |