ECOLINE BAG FILTER HOUSINGS

Inexpensive bag filter housings for light duty applications

Call us at 908.362.9981 to speak with a sales engineer

The

ECOLINE model bag filter housing is a "light duty" design for

applications having operating pressures ≤ 100 PSI. The "ECO"

portion of "ECOLINE" refers to its cost being less expensive than

our other bag filter vessel designs. A significant reason for the

reduced cost is the manufacturing technique used for forming the

cylindrical housing - a process called hydroforming.

Hydroforming the bag filter housing body eliminates the vertical

weld seam used for traditionally fabricated bag filter housings and

thus also eliminates welding, polishing and NDE procedures

associated with those tasks. Another cost savings feature is

the V-Clamp style

quick-opening closure which simplifies filter bag access. The

clamp can be opened/closed without special tools. ECOLINE bag filter housings are only

available in 316SS material of construction and with 2" FNPT

(threaded) inlet/outlet connections.

The

ECOLINE model bag filter housing is a "light duty" design for

applications having operating pressures ≤ 100 PSI. The "ECO"

portion of "ECOLINE" refers to its cost being less expensive than

our other bag filter vessel designs. A significant reason for the

reduced cost is the manufacturing technique used for forming the

cylindrical housing - a process called hydroforming.

Hydroforming the bag filter housing body eliminates the vertical

weld seam used for traditionally fabricated bag filter housings and

thus also eliminates welding, polishing and NDE procedures

associated with those tasks. Another cost savings feature is

the V-Clamp style

quick-opening closure which simplifies filter bag access. The

clamp can be opened/closed without special tools. ECOLINE bag filter housings are only

available in 316SS material of construction and with 2" FNPT

(threaded) inlet/outlet connections.

A nice feature of the ECOLINE bag filter housing is that their

chamber cover has a

concave design to increase ullage within the

vessel, thus reducing spillover and inadvertent contact with the process

fluid. If you require a 150# design, consider the

FLOWLINE II

bag filter housing which shares the same hydro formed

construction and evacuation cover design.

A nice feature of the ECOLINE bag filter housing is that their

chamber cover has a

concave design to increase ullage within the

vessel, thus reducing spillover and inadvertent contact with the process

fluid. If you require a 150# design, consider the

FLOWLINE II

bag filter housing which shares the same hydro formed

construction and evacuation cover design.

Optional features for ECOLINE filter bag vessels are differential pressure taps, powder epoxy coated adjustable steel mounting legs and the HAYFLOW upgrade option for increased flow capacity. These are also available in miniature sizes using #3 and #4 size filter bags for low flow rate applications benefitting from a smaller vessel size and reduced cost (refer to our MINILINE bag filter page).

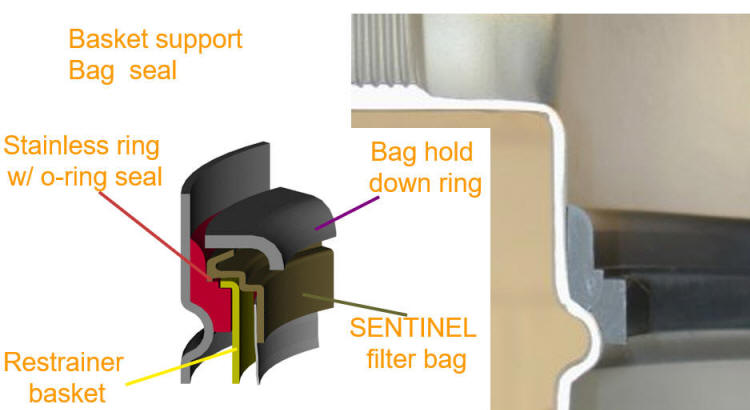

Filter Bag Seal for ECOLINE bag filter housings

The sealing of the filter bag within the vessel begins with an o-ring supported by the formed bead around the circumference of the vessel. The restrainer basket, responsible for supporting the filter bag, mounts to this o-ring seal. Next the sealing ring of the filter bag either lays across both the o-ring and restrainer basket interface (as illustrated above, the SENTINEL RING design) or via a snap ring sealed to the inner circumference of the restrainer basket. Finally the stainless steel hold down ring provides downward pressure as it is sandwiched between the cover and o-ring/basket/filter bag. The sealing efficiency achieved wit this design is suitable for most nominally rated filtration applications. If you require an absolute rated filter bag or are filtering to less than 50 microns you should consider the TOPLINE bag filter housing design due to its higher efficiency seal.

Flexible Port Configuration enables you to plumb the ECOLINE three ways:

Outline Drawings: